Overview:

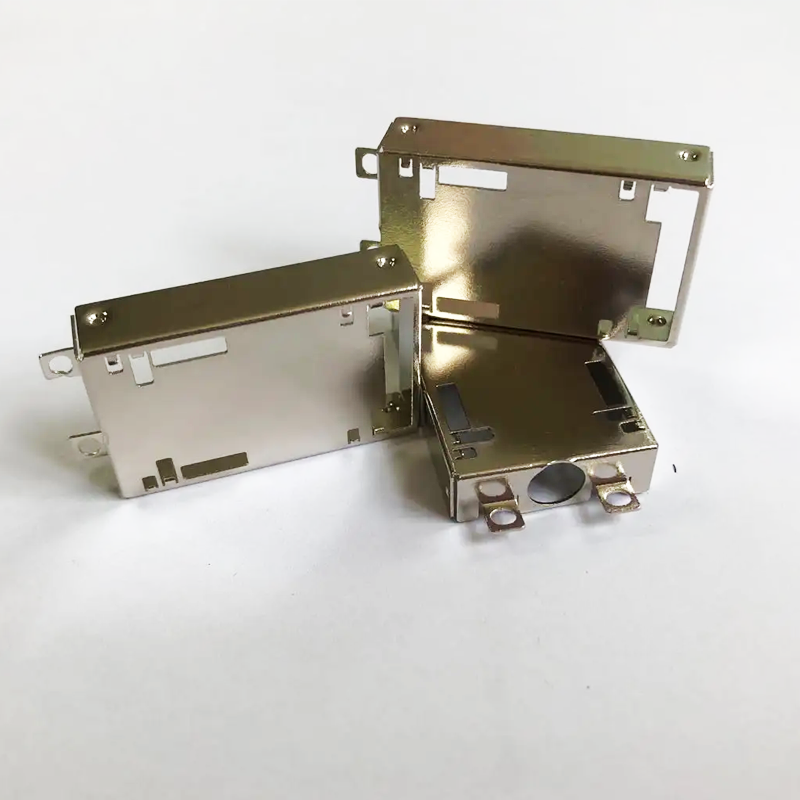

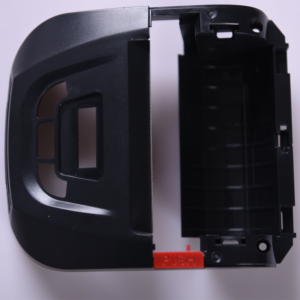

EMI shielding components, including enclosures and housings, are meticulously engineered to safeguard electronic devices from external electromagnetic interference (EMI) by utilizing conductive or magnetic materials. These high-performance components effectively block electromagnetic fields, ensuring optimal functionality and reliability of the device. Specifically designed for PCB protection, they maintain signal integrity and prevent disruption or malfunction caused by external sources. At our factory, we specialize in precision metal stamping processes to manufacture high-quality shielding components, ensuring superior EMI shielding performance for critical applications across a wide range of industries. Our metal stamping capabilities guarantee precision, consistency, and durability in every component we produce.

Features:

| Feature | Details |

| Brand Name | OEM |

| Standards | ROHS, ISO,IATF |

| Certifications | ISO 9001, IATF 16949 |

| Materials | Brass, Copper, Stainless Steel |

| Processing | Stamping, Drawing, CNC Machining |

| Surface Treatment | Chromium, Polishing, Painting, etc. |

| Service | OEM Accepted |

| Business Type | Factory and Trader |

| Quality Control | 100% Inspection Before Shipment |

| Shipping Methods | Sea, Air, Courier, Express |

Benefits of Our Shielding Enclosures:

- Available in a variety of sizes, including oval, round, tall, and compact options

- Features minimal or zero gap designs with interlocking capabilities

- Ideal for applications requiring efficient heat shielding

- Optimized for radio frequency (RF) protection

- Manufactured using advanced Four Slide/Multi Slide stamping press technology for precision and efficiency

Surface Treatment Options:

- Chromium Plating– Provides enhanced corrosion resistance and durability while offering a smooth, reflective finish.

- Nickel Plating– Improves conductivity and provides excellent protection against corrosion, oxidation, and wear.

- Powder Coating– Offers robust environmental protection with a durable, high-quality finish resistant to chipping, scratching, and fading.

- Polishing– Ensures a smooth, shiny surface that reduces surface friction and improves overall appearance, often used for aesthetic and functional purposes.

Quality Assurance:

At Topmetalstamping, we prioritize quality with a robust assurance process starting from feasibility reviews and run-at-rate studies before large-scale production. Our advanced quality management system integrates in-line vision systems and sensors for real-time inspection, ensuring 100% quality and zero defects. Certified to IATF16949 and ISO9001 standards, we deliver high-quality EMI shielding components with precision and reliability, backed by a dedicated team and advanced technology to meet the highest industry standards.

Factory Show:

We operate a fully equipped facility with a wide range of advanced machinery, including 25 punch presses (from 25 to 300 tons), precision wire EDM machines, grinding tools, welding equipment, and ultrasonic cleaning systems. To enhance the durability and aesthetics of our metal stamping products, we offer various plating options such as electroplating, zinc, nickel, chrome plating, and anodizing. Our state-of-the-art plating processes ensure consistent quality, corrosion resistance, and adherence to industry standards. Combined with rigorous quality control and automated production lines, we guarantee top-tier metal stamping products that meet the highest standards of performance and reliability.

Reviews

There are no reviews yet.