Introduction:

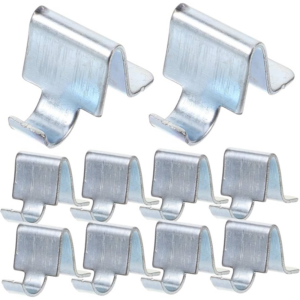

Spring metal clips are essential fasteners known for their versatility and efficiency in securing components. Utilized across various applications, these clips offer a resilient grip, ensuring stability and proper alignment of connected parts. Their primary advantage lies in their spring-like characteristics, allowing them to flex and absorb shocks or vibrations, thus providing a secure and reliable connection.

– Quotation: Tailored to your specifications +including size, material, thickness, processing requirements, and desired technology.

– Material: Options include carbon steel, SPCC, SGCC, stainless steel, aluminum, brass, copper, etc.

– Processing: Utilizes laser cutting, precision stamping, bending, CNC punching, grinding, riveting, drilling, welding, and more.

– Tolerance: Maintains a tolerance of ±0.1mm with 100% QC quality inspection before delivery, accompanied by quality inspection documentation.

– Size: Accepts custom sizes to meet specific project requirements.

– Color: Offers a variety of color options such as white, blank, silver, red, grey, Pantone, etc.

– Drawing Format: Accepts DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI, PDF, JPG, and Draft formats for drawings.

– Price Term: Provides flexibility with terms including EXW, FOB, CIF, DDP, etc.

– Payment Term: For samples, requires 100% payment before production. For mass production, requests 50% deposit in advance with the balance due before delivery.

– Certificate: Complies with ISO9001:2015/SGS certification standards.

Surface Finishes:

- Zinc Plating:Enhances corrosion resistance and improves aesthetics.

- Nickel Plating:Increases corrosion resistance and surface hardness.

- Powder Coating: Provides a durable and visually appealing finish, safeguarding against corrosion and wear.

- Anodizing:Primarily for aluminum clips, forms a protective oxide layer for enhanced corrosion resistance.

- Passivation:Utilized for stainless steel clips, eliminates free iron for improved corrosion resistance.

- Electroplating:Applies a thin layer of metal (e.g., chrome or gold) for enhanced corrosion resistance and appearance.

Selection of the appropriate surface treatment depends on factors such as clip material, intended application, and desired aesthetic attributes.

Reviews

There are no reviews yet.