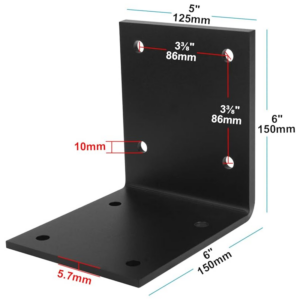

L Shape 90 Degree Countertop Support Fireplace Mental Brackets

Features:

| Features | Anti-corrosion, wear-resistant, anti-rust, smooth surface, burr-free edges |

| Unit Count | 4.0 Count |

| Mounting Type | Corner Mount |

| Part Number | ZJ16-B-T4 |

| Item Weight | 4.64 pounds |

| Product Dimensions | 5 x 1.5 x 5 inches |

| Country of Origin | Xiamen,China |

| Item model number | ZJ16-B-T4 |

| Size | 5″(127mm) |

| Finish | Powder Coated |

| Shape | Rectangular |

| Included Components | 4 PCS Heavy Duty Steel Black Bracket |

| Batteries Included? | No |

| Batteries Required? | No |

Description:

The 90 Degree Countertop Support Fireplace Mental Brackets are robust, heavy-duty steel brackets designed to securely support countertops and fireplace mantels. These brackets are constructed using a precision welding process, followed by a black powder-coated finish for enhanced durability and resistance to corrosion, rust, and wear. Their design allows for a clean, seamless installation, providing both functionality and an aesthetically pleasing look. Each bracket can support up to 400 lbs, making them ideal for heavy countertops and mantels.

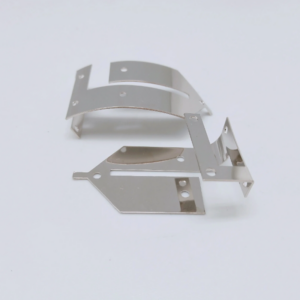

Surface Treatments for Fireplace Mantel Brackets:

- Black Powder Coating:

A dry powder is applied and cured under heat, forming a durable, smooth, and protective layer that resists corrosion, rust, and wear.

- Galvanization:

A zinc coating is applied to the steel surface, providing excellent protection against rust and corrosion, ideal for both indoor and outdoor use.

- Anodizing:

An electrochemical process that thickens the natural oxide layer on the metal surface, enhancing corrosion resistance and wear properties.

- Painted Finish:

A layer of paint is applied to the brackets, offering customizable color options and additional protection against environmental elements.

- Brushed Metal:

The surface is mechanically brushed to create a uniform texture, providing a sleek, modern appearance while offering some resistance to wear and corrosion.

Production Process of Fireplace Mantel Brackets:

- Material Selection:

High-quality steel is chosen for its durability and strength, ensuring the brackets can support significant weight.

- Cutting:

The steel is cut into the required shapes and sizes using precision cutting tools such as lasers or saws to ensure accuracy.

- Forming:

The cut steel pieces are then bent or formed into the desired bracket shape using hydraulic presses or bending machines.

- Welding:

Components of the brackets are welded together to form a solid, cohesive unit. Skilled welders ensure the joints are strong and reliable.

- Drilling:

Holes are drilled into the brackets to allow for mounting. This step ensures that the holes are precisely placed to match standard bolt sizes.

- Surface Treatment:

The brackets undergo a surface treatment process, such as powder coating, galvanization, or anodizing, to enhance corrosion resistance and aesthetic appeal.

- Quality Inspection:

Each bracket is thoroughly inspected for defects in material, workmanship, and finish. This step ensures that only high-quality products reach the customers.

- Packaging:

The finished brackets are securely packaged to protect them during transportation and handling. Packaging includes padding and sturdy boxes to prevent damage.

This meticulous production process ensures that each fireplace mantel bracket is robust, reliable, and visually appealing.

Reviews

There are no reviews yet.