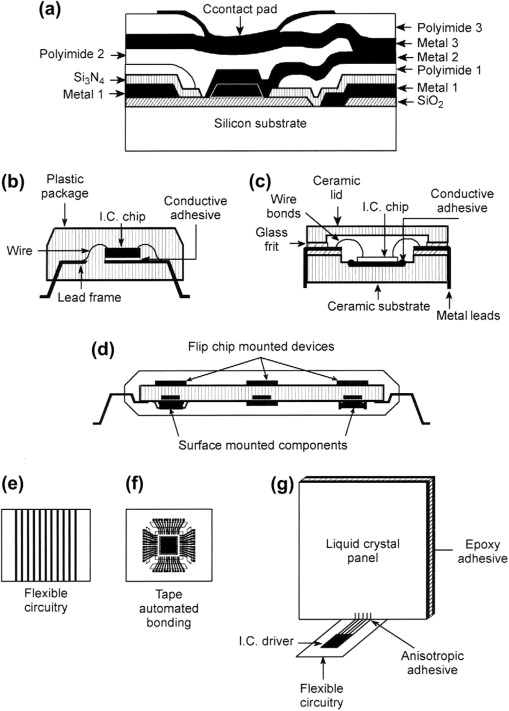

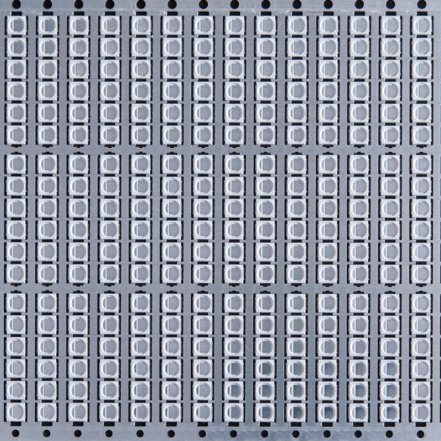

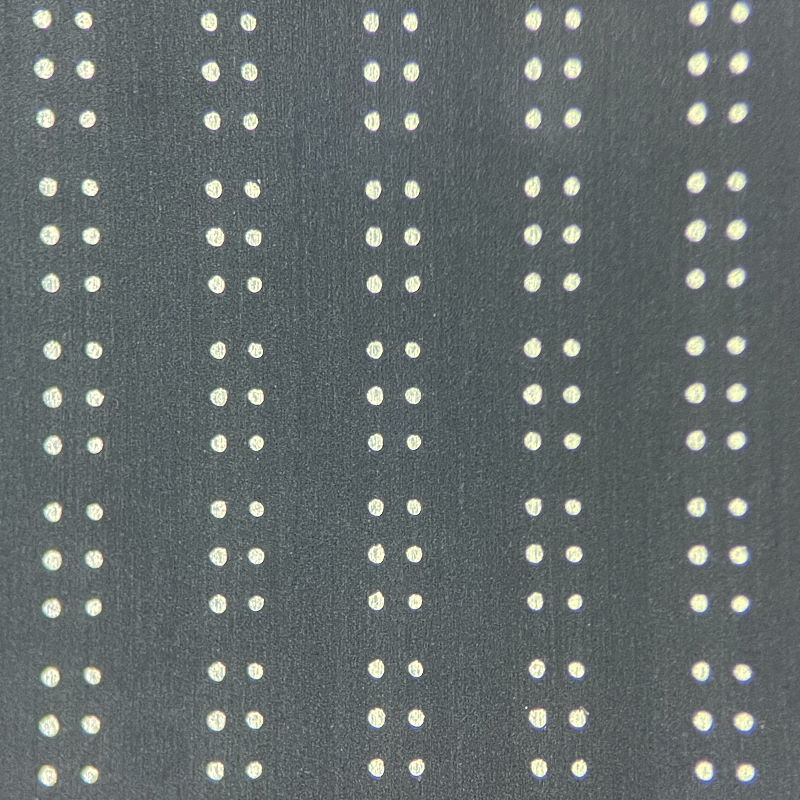

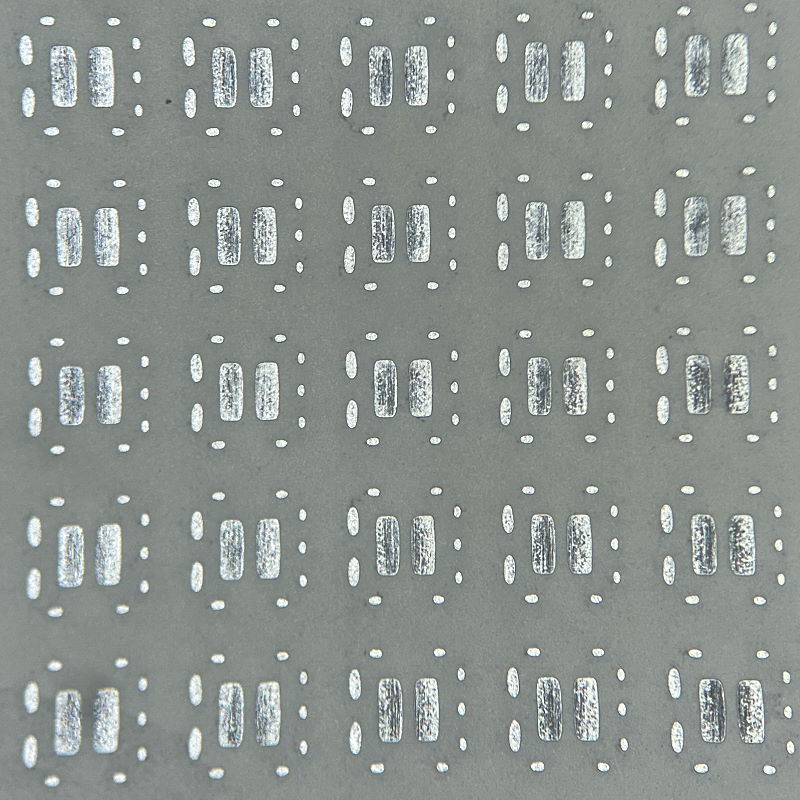

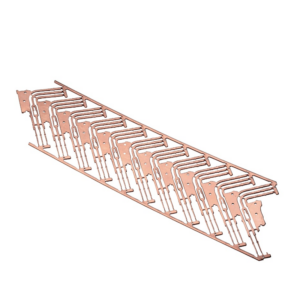

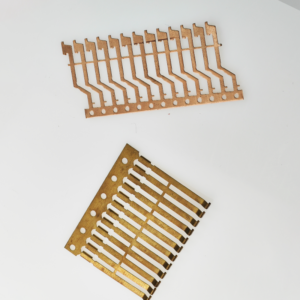

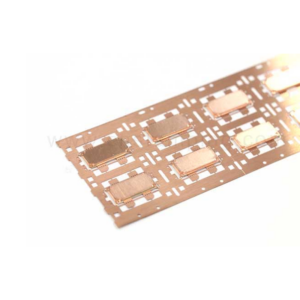

Lead frames for LED substrate applications are essential components that provide mechanical support and electrical connections for LED chips. Made from high-quality materials, these lead frames ensure optimal thermal conductivity, durability, and long-term performance of LED lighting systems. Designed for precision and reliability, they help enhance the efficiency and lifespan of LED devices. Ideal for a range of lighting applications, lead frames for LED substrates are manufactured using advanced processes to meet industry standards and deliver superior results.

Basic Information

– Surface Treatment: Electroplating

– Forming Process: Metal Stamping Parts

– Surface Finish Options: Nickel Plating, Sn Plating, Tin Plating, Zinc Plating

– Sample Availability: Available

– Tolerance: ±0.001 mm

– Size: Customizable as per requirement

– Application: Industrial, Furniture, Automotive, Motorcycle, etc.

– Manufacturing Approach: Metal Stamping, Cutting, Punching, Bending, Welding

– Transport Packaging: OPP Bag, Box, or Custom

– Specification: Customized

– Origin: Xiamen, China

One-Stop Service for Metal Stamping Parts

– Design and Prototyping: We provide end-to-end design services, including CAD modeling and prototyping, to ensure your metal stamping parts meet precise specifications and functionality requirements.

– Tooling and Die Development: Our facilities handle the complete tooling and die creation process, utilizing advanced technology to produce high-precision tools and dies that ensure consistent part quality.

– Metal Stamping Production: We offer comprehensive metal stamping services, capable of handling a wide range of materials and sizes. Our equipment supports both high-volume production and custom orders with exceptional accuracy.

– Surface Treatment: Enhance the performance and appearance of your parts with our surface treatment options, such as electroplating, coating, and polishing, tailored to meet your specific requirements.

– Quality Control: Our rigorous quality control process includes thorough inspections and testing to ensure that every part adheres to the highest standards of precision and durability.

– Custom Packaging and Logistics: We provide custom packaging solutions and manage logistics to deliver your stamped parts safely and efficiently, ensuring they arrive on time and in optimal condition.

– Post-Production Support: Our service extends beyond manufacturing, offering ongoing support to address any issues, provide maintenance, and ensure that your needs are continuously met.

Advantages of Our Product

-

Precision Engineering

– Our metal stamping parts are crafted with high precision, ensuring exact dimensions and consistent quality for optimal performance.

-

High Durability

– Utilizing robust materials and advanced stamping techniques, our parts exhibit superior strength and durability, suitable for demanding applications.

-

Cost-Effective Production

– The efficiency of our stamping processes minimizes material waste and reduces production costs, offering economical solutions for large-scale manufacturing.

-

Rapid Production Turnaround

– Our state-of-the-art equipment and streamlined processes enable quick production cycles, meeting tight deadlines and high-volume demands.

-

Versatile Applications

– Our metal stamping parts are versatile and can be customized to fit a wide range of industries including automotive, aerospace, and industrial applications.

Reviews

There are no reviews yet.