Overview

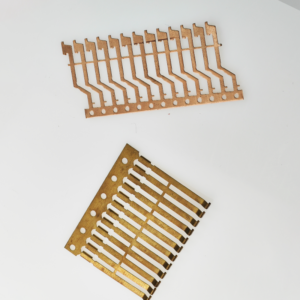

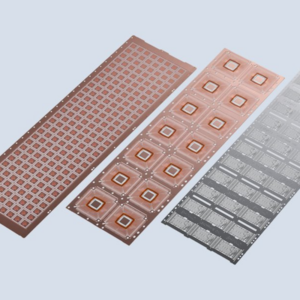

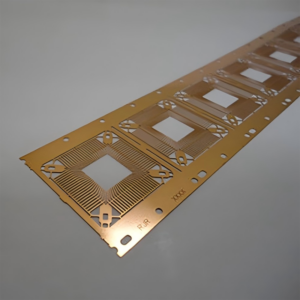

Lead frames for the semiconductor and electronics industry are essential components used to connect integrated circuits (ICs) to external circuits. These precision-engineered metal frames provide a reliable mechanical and electrical interface, ensuring optimal performance and signal integrity. Typically made from copper or alloy materials, lead frames are designed through a stamping process, offering high durability and excellent conductivity. They are widely used in various semiconductor packaging applications, including ICs, transistors, and diodes. Available with different surface finishes such as gold, silver, or nickel plating, lead frames play a crucial role in enhancing the efficiency and reliability of electronic devices, including smartphones, computers, and automotive electronics.

![]()

Basic Information:

- Material:Copper-1100

- Post Process:Passivation, Gold plating, Silver plating, Nickel plating, Tin plating

- Surface Finish Options:Gold Plating, Silver Plating, Nickel Plating, Tin Plating

- Sample Availability:Available

- Tolerance:±0.001 mm

- Size:Customizable

- Manufacturing Approach:Metal Stamping, Cutting, Punching, Bending, Welding

- Transport Packaging:OPP Bag, Box, or Custom

- Specification:Customized

- Origin:Xiamen, China

- Applications:Used in the semiconductor and electronics industry for ICs, transistors, diodes, sensors, and other electronic components.

![]()

OEM Services for Metal Stamping Parts

– Custom Design: We offer tailored design services for OEM metal stamping parts, leveraging advanced CAD software to create designs that align with your specifications and industry standards.

– Material Sourcing: Select from a diverse range of high-quality metals and alloys suited to your application requirements. Our team ensures that the chosen materials meet durability and performance criteria.

– Tooling and Die Fabrication: We develop precision tooling and dies using state-of-the-art machinery, ensuring high accuracy and consistency in part production. Our tooling process is optimized for both efficiency and quality.

– Manufacturing Capabilities: Our advanced metal stamping equipment handles various production volumes, from prototypes to large-scale runs, delivering parts with precise dimensions and reliable performance.

– Surface Finishing: Enhance the functionality and aesthetics of your stamped parts with our surface finishing options, including electroplating, polishing, and coating, tailored to meet your specific requirements.

– Quality Assurance: Rigorous quality control procedures are in place to ensure each part meets stringent standards. We conduct comprehensive inspections and tests to guarantee consistency and reliability.

– Custom Packaging and Logistics: We provide customized packaging solutions and manage logistics to ensure your parts are delivered securely and on schedule, according to your needs.

– Comprehensive Support: From initial consultation to post-production support, our dedicated team provides ongoing assistance to ensure your satisfaction and address any concerns that arise.

Why Choose Us?

Industrial Experience

We have been specializing in the spring industry since 1998, bringing years of expertise and knowledge to our field.

Sample Availability

We can provide samples for your approval within 7 days. Samples are free of charge if we have the tool readily available.

Fast Delivery

Our standard delivery time is typically within 10 days.

Exceptional Service and Quality

Our business philosophy is centered on offering the best competitive pricing, excellent service, and superior quality.

Reviews

There are no reviews yet.