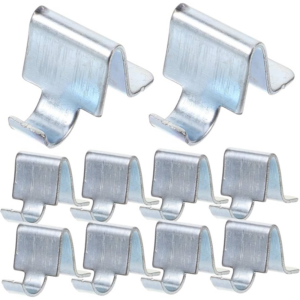

We specialize in the design, manufacturing, and assembly of custom metal clips and fasteners in a wide range of shapes and sizes. Our services include secondary processes such as vacuum hardening, oil quenching, and Austempering, along with extensive plating options. We offer various sizes to meet the specific needs of each application, ensuring the perfect fit. Industrial clips and fasteners are available in different material compositions to match application requirements and budget constraints. Contact us for a competitive quote tailored to your clip size, shape, and material specifications.

Basic Information

Material: Available Carbon Steel, Stainless Steel, Spring Steel, Bronze, Brass, Copper Alloy, Aluminum Alloy, Tinplate, Nickel Silver

Surface Treatment :Zinc/Nickel/Chrome/Tin Plating (Color or Natural), Galvanization, Anodizing, Oil Spraying, Powder Coating, Polishing, Passivation, Brushing, Wire Drawing, Painting, etc.

Metal Processing: Available Tooling Making, Prototype, Cutting, Stamping, Welding, Tapping, Bending and Forming, Machining, Surface Treatment, Assembly

Specification :OEM, As per Client’s Drawing or Sample

Certificate :ISO9001:2008, SGS

Production Capabilities: a) Stamping: 16 Tons – 500 Tons

b) Welding: Carbon Dioxide Welding, Spot Welding, TIG Welding, Automated Robotic Welding

c) Machining: CNC Lathe and Machine Centers, Light Machines (Drilling, Milling, and Tapping)

d) Surface Treatment: Galvanizing, Anodized, Zinc/Nickel/Chrome/Tin Plating, Powder Coating, Painting, etc.

Software: AutoCAD, SolidWorks, PDF

Application: Automobile, Furniture, Electronics, Agriculture, Appliance, Lighting, Industrial, Building, etc.

Advantages of Our Product

Lighter weight

Lower cost

Higher load-carrying capacities

More resistant to shock loads and oscillations

More tolerant of shaft misalignments

Reviews

There are no reviews yet.