Overview

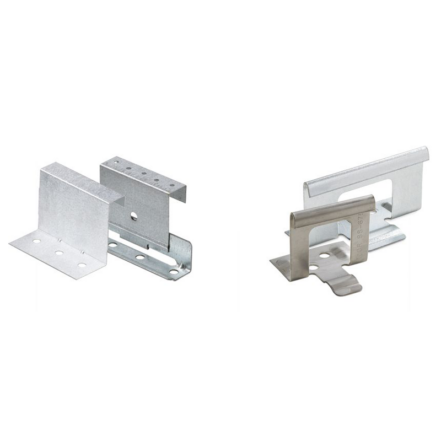

Metal roof clips are essential components used to secure metal roofing panels to the structure, allowing for thermal expansion and contraction while maintaining a strong and stable attachment. These clips, typically made from durable materials like stainless steel or galvanized metal, are designed to resist corrosion and ensure long-lasting performance. Collaborating with reputable manufacturers, these clips are precisely engineered to meet industry standards, offering compatibility with various roofing systems and ensuring a secure, weather-resistant installation.

Basic Information

– Surface Treatment: Electroplating

– Forming Process: Metal Stamping Parts

– Surface Finish Options: Nickel Plating, Sn Plating, Tin Plating, Zinc Plating

– Sample Availability: Available

– Tolerance: ±0.001 mm

– Size: Customizable as per requirement

– Application: Industrial, Furniture, Automotive, Motorcycle, etc.

– Manufacturing Approach: Metal Stamping, Cutting, Punching, Bending, Welding

– Transport Packaging: OPP Bag, Box, or Custom

– Specification: Customized

– Origin: Xiamen, China

OEM Services for Metal Stamping Parts

– Custom Design: We offer tailored design services for OEM metal stamping parts, leveraging advanced CAD software to create designs that align with your specifications and industry standards.

– Material Sourcing: Select from a diverse range of high-quality metals and alloys suited to your application requirements. Our team ensures that the chosen materials meet durability and performance criteria.

– Tooling and Die Fabrication: We develop precision tooling and dies using state-of-the-art machinery, ensuring high accuracy and consistency in part production. Our tooling process is optimized for both efficiency and quality.

– Manufacturing Capabilities: Our advanced metal stamping equipment handles various production volumes, from prototypes to large-scale runs, delivering parts with precise dimensions and reliable performance.

– Surface Finishing: Enhance the functionality and aesthetics of your stamped parts with our surface finishing options, including electroplating, polishing, and coating, tailored to meet your specific requirements.

– Quality Assurance: Rigorous quality control procedures are in place to ensure each part meets stringent standards. We conduct comprehensive inspections and tests to guarantee consistency and reliability.

– Custom Packaging and Logistics: We provide customized packaging solutions and manage logistics to ensure your parts are delivered securely and on schedule, according to your needs.

– Comprehensive Support: From initial consultation to post-production support, our dedicated team provides ongoing assistance to ensure your satisfaction and address any concerns that arise.

Why Choose Us?

-

Expertise in OEM Parts Production

– Description: Specializing in the production of OEM parts, including metal stamped, machined, deep drawn, and sheet metal formed components. We also offer a range of finishing options to meet diverse requirements.

-

Advanced Machinery and Equipment

– Description: Equipped with a comprehensive range of machinery for punching, welding, CNC, milling, and grinding. Our facility employs reliable equipment and advanced technology to ensure high-quality production.

-

Skilled Workforce and Technical Expertise

– Description: Our team includes experienced technicians dedicated to technical development, skilled workers, professional engineers, and a robust R&D center. We also have an exceptional foreign trade team, all committed to supporting our customers with enthusiasm and expertise.

-

Design-Based Customization

– We offer extensive customization based on your design requirements. Our experienced engineers collaborate closely with you to develop molds that precisely match your specifications, ensuring optimal performance and functionality.

-

Sample-Based Customization

– We provide customization based on sample submissions. This process allows us to replicate and enhance existing designs, ensuring the final product aligns perfectly with your expectations.

Reviews

There are no reviews yet.