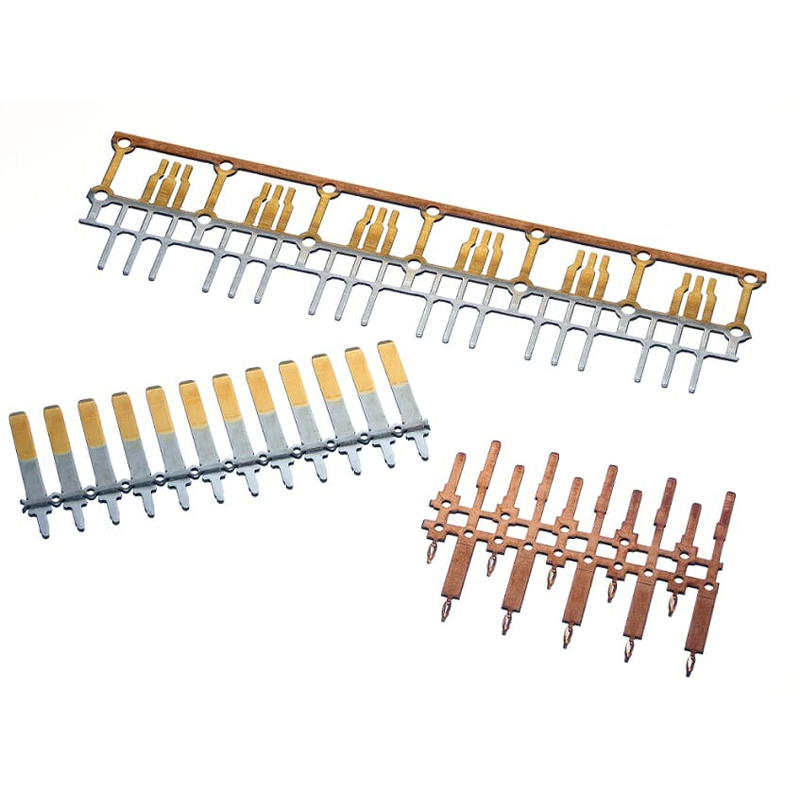

Metal stamping connector is a precision-engineered electrical component made through a stamping process, where metal sheets are shaped and cut to create connectors that establish electrical contacts. These connectors are commonly used in a wide range of electronic devices, automotive applications, and industrial machinery. They offer reliable electrical conductivity, compact design, and durability, making them ideal for applications that require secure and efficient electrical connections. Metal stamping connectors are typically made from materials like copper, brass, or stainless steel, and are available in various shapes and sizes to meet specific design requirements.

Features

Place of Origin: Xiamen, China

Brand Name :OEM

Material: Stainless Steel/ Metal

Type :Hardware Parts

Size: Customized Size

Surface treatment: Galvenized/ Custom

Certificate ISO9001:2015/IATF16949

Delivery :by sea/air/express

Service Customized :OEM

Application :Industrial

Advantages of Our Metal Stamping Parts

-

Precision Engineering

– Our metal stamping parts are crafted with high precision, ensuring exact dimensions and consistent quality for optimal performance.

-

High Durability

– Utilizing robust materials and advanced stamping techniques, our parts exhibit superior strength and durability, suitable for demanding applications.

-

Cost-Effective Production

– The efficiency of our stamping processes minimizes material waste and reduces production costs, offering economical solutions for large-scale manufacturing.

-

Rapid Production Turnaround

– Our state-of-the-art equipment and streamlined processes enable quick production cycles, meeting tight deadlines and high-volume demands.

Factory Show

Reviews

There are no reviews yet.