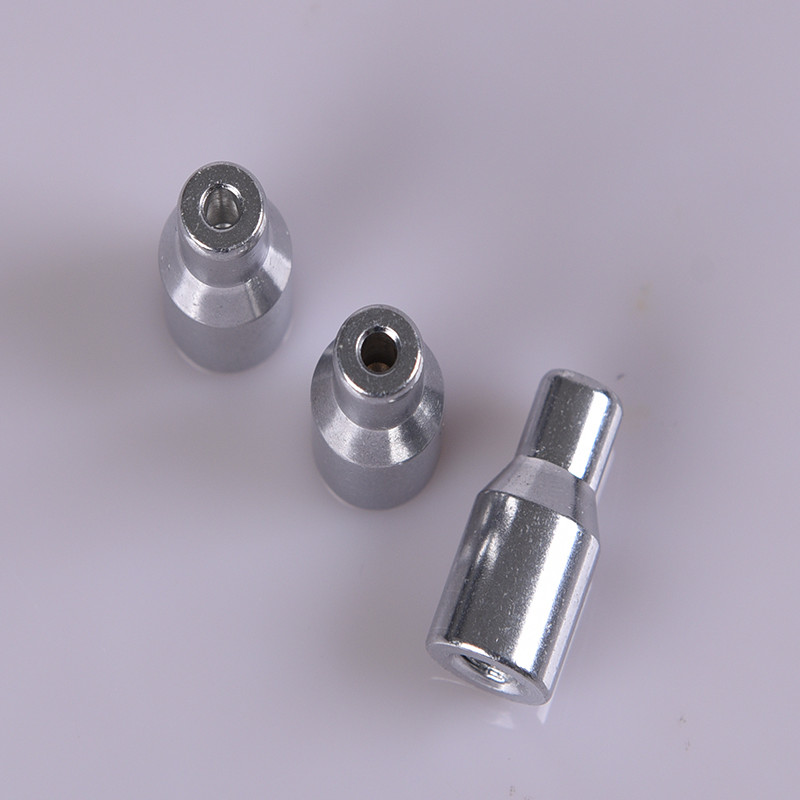

Description:

Metal Stamping Connector Parts are precision-engineered components used in various applications, particularly in the automotive industry. These parts are typically made from high-quality materials such as brass, copper, stainless steel, and aluminum, selected for their conductivity, durability, and corrosion resistance. In automotive applications, metal stamping connector parts offer significant advantages, including enhanced electrical performance, reliability under harsh conditions, and the ability to withstand high vibration and temperature variations. Their precise manufacturing ensures a secure and efficient connection, crucial for maintaining system integrity in automotive electrical systems. If you require custom connector parts, we offer tailored solutions, including a wide range of sizes, colors, and functionalities to suit your specific needs. Contact us for more details and to discuss your project requirements.

Characteristics:

| Attribute Details | Description |

| Metal Material | Copper, Brass, Iron, Steel, etc. |

| Surface Finish | Plating, Anodized, Powder Coating, Painting, etc. |

| Delivery Time | First Custom Sample Can Be Offered Within 30 Working Days |

| Our Products | Automotive Spare Parts |

| Transport Package | Custom |

| Size | Custom |

| Trademark | OEM |

| Origin | Xiamen, China |

| Production Capacity | 50,000 PCS/Day |

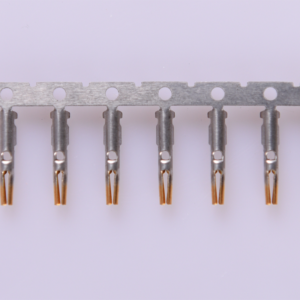

Production Process:

- Material Selection: High-quality metals such as copper, brass, or steel are selected based on their conductivity, strength, and suitability for automotive applications.

- Tooling and Die Design: Custom tooling and die sets are designed using advanced CAD software to ensure precise and efficient stamping of the connector parts. This step ensures that the final parts meet specific dimensional requirements and performance standards.

- Metal Stamping: The selected material is fed into stamping presses, where high pressure is applied to form the metal into the desired shape. This process involves using progressive or single-step dies to create the connector parts with high accuracy.

- Secondary Operations: Additional processes such as punching, trimming, bending, or welding may be used to refine the parts further and achieve the necessary functionality and fit.

- Surface Treatment: The connector parts undergo surface treatments such as plating, anodizing, or powder coating to enhance their corrosion resistance, appearance, and durability, ensuring they meet the requirements for automotive applications.

- Quality Control and Inspection: Rigorous inspection is conducted at various stages of production to ensure the parts meet strict quality standards. This includes dimensional checks, visual inspections, and performance testing.

- Packaging and Shipping: Once the connector parts pass quality checks, they are carefully packaged to prevent damage during transport and delivered to clients on time, meeting the required specifications.

Surface Treatment Options:

- Gold Electroplating: A premium coating process that applies a thin layer of gold to enhance electrical conductivity, corrosion resistance, and provide superior durability, commonly used for high-performance and high-reliability components.

- Silver Electroplating: A process where a layer of silver is deposited on the surface to improve electrical conductivity, provide superior corrosion resistance, and enhance the component’s solderability, especially in electronics and automotive applications.

- Nickel Electroplating: A widely used coating process that provides a hard, corrosion-resistant finish, offering increased wear resistance, improved aesthetics, and enhanced protection against harsh environments, ideal for industrial and automotive applications.

- Tin Electroplating: A cost-effective coating method that provides excellent corrosion protection, enhances solderability, and improves overall durability, often used in connectors and electrical components to prevent oxidation and ensure reliable performance.

Our Factory:

Our manufacturing facility is equipped with a wide range of advanced equipment designed to ensure top-tier production quality. We operate 25 punch presses with capacities ranging from 25 tons to 300 tons, along with precision wire EDM machines, grinding and polishing tools, welding stations, ultrasonic cleaning systems, and advanced metal stamping inspection instruments, ensuring precise dimensional control and product consistency.

In addition to these robust manufacturing capabilities, we offer comprehensive metal plating solutions, including electroplating, zinc plating, nickel plating, chrome plating, and anodizing. These treatments not only enhance the durability and appearance of our metal stamping products but also improve their functionality and corrosion resistance. Our plating facilities are equipped with cutting-edge technology to ensure reliable finishes that meet or exceed industry standards.

With a strong emphasis on quality, we integrate advanced mechanical equipment, automated production lines, and stringent quality control protocols to deliver metal stamping products that are durable, high-performance, and meet the highest industry standards.

Reviews

There are no reviews yet.