Overview:

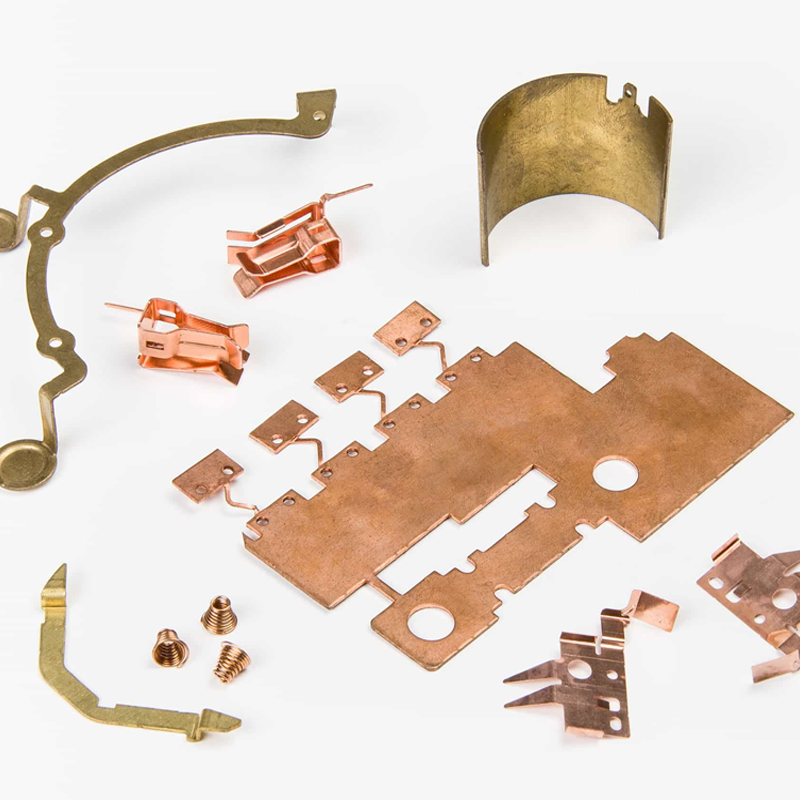

Metal Stamping Electrical Copper Contacts are high-precision components manufactured through advanced metal stamping techniques. Utilizing copper for its superior electrical conductivity and durability, these contacts are designed to deliver exceptional reliability in a wide range of electrical applications. We also offer alternative materials such as brass, stainless steel, and phosphor bronze, each selected to meet specific performance requirements. Our expertise in precision stamping ensures that each contact is produced to the highest standards, with customization options available to meet your exact specifications. For tailored solutions and top-quality electrical contacts, reach out to us for further details or a personalized quote.

Details:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Process | Metal Stamping |

| Mould | Custom Design |

| Thickness | 0.15mm |

| Tolerance | +/- 0.02 |

| Test | Tensile Test |

| Property | Good Connecting |

Surface Treatments:

-

Anodizing

An electrochemical process that thickens the natural oxide layer on metal surfaces, providing enhanced corrosion resistance, superior wear resistance, and an improved aesthetic finish.

-

Heat Treatment

A precision-controlled process used to modify the material’s properties, including strength, hardness, and durability, through specific cycles of heating and cooling.

-

Electrophoresis Coating

A coating process in which charged particles are driven onto a component’s surface using an electric field, forming a uniform, highly durable, and corrosion-resistant layer with excellent adhesion.

-

Powder Coating

A dry finishing technique where powdered coating material is electrostatically applied to the surface and cured with heat, resulting in a robust, long-lasting finish that resists chipping, scratching, and color fading.

Production process:

-

Design and Prototyping

The initial design and prototyping phase ensures that the electrical copper contacts meet both functional and precision requirements, laying the foundation for high-quality production.

-

Laser Cutting

Advanced laser cutting technology is employed to achieve precise, clean cuts of materials, ensuring the parts are shaped accurately to the specified dimensions.

-

Inspection

Thorough quality inspections are conducted at every stage to verify dimensional accuracy, material integrity, and conformance to technical specifications.

-

Grinding

Precision grinding is used to achieve smooth surface finishes and exacting tolerances, ensuring the components meet stringent performance standards.

-

Assembly

The components are meticulously assembled, with particular attention paid to alignment and connection integrity to ensure optimal electrical functionality.

-

Progressive Stamping

Progressive stamping is employed to shape the copper contacts in multiple stages, enabling the efficient production of high-volume parts with consistent precision.

-

Heat Treatment

Heat treatment is applied to enhance the material properties, including the strength and durability of the copper contacts, ensuring long-term reliability and performance.

-

Surface Treatment

Surface treatments, such as plating or coating, are applied to improve corrosion resistance, enhance electrical conductivity, and ensure a superior finish.

-

Testing

Comprehensive performance testing, including tensile and electrical conductivity tests, is conducted to ensure the copper contacts meet industry standards and perform reliably in their applications.

-

Final Inspection

A final inspection is carried out to confirm that all components meet the required quality standards and customer specifications prior to packaging.

-

Packaging

The finished copper contacts are carefully packaged in protective materials to prevent damage during transport, ensuring they reach the customer in optimal condition.

-

Shipping

The completed parts are shipped to the customer with a focus on timely delivery and safe handling, ensuring the products arrive as expected.

Why Partner with Us?

-

Extensive Industry Expertise

With over 20 years of specialized experience in metal mold design and precision stamping, we bring unmatched expertise to ensure the highest standards in manufacturing quality.

-

Global Experience and Proven Track Record

Our extensive history of developing international partnerships has enabled us to successfully serve a diverse global client base, demonstrating reliability and expertise in export operations.

-

Certified Excellence

We are ISO 9001 and IATF 16949 certified, adhering to globally recognized quality management standards to guarantee exceptional manufacturing performance and consistency.

-

Environmental and Safety Compliance

All our products are fully RoHS-compliant, with detailed material reports available to confirm adherence to stringent environmental and safety regulations, ensuring both regulatory compliance and sustainability.

Factory Overview:

This combination of professional and automated production lines, advanced mechanical equipment, rigorous quality control measures, and high-quality plating processes ensures we deliver metal stamping products of the highest standard.

Reviews

There are no reviews yet.