Overview:

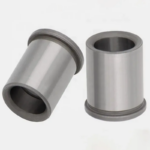

Metal stamping sleeves are precision-engineered components made through advanced stamping processes such as punching, cutting, and forming. These sleeves are typically produced from high-quality materials like stainless steel, carbon steel, brass, and aluminum, ensuring exceptional strength, durability, and resistance to wear and corrosion. Designed for various applications, metal stamping sleeves provide reliable performance in industries like automotive, electronics, and manufacturing. At our company, we offer custom metal stamping services, allowing you to tailor the dimensions, shapes, and finishes of your sleeves to meet specific requirements. Our products are built to last, providing long-term durability and functionality for a wide range of applications. Contact us today to customize your metal stamping sleeves for superior performance!

Features:

| Category | Details |

| Certification | ISO9001 |

| Customized | Yes |

| Material | Brass |

| Application | Metal Processing Machinery Parts |

| Process | Lathing, CNC, Centerless Grinding |

| Tolerance | +/- 0.005 or Meet Customer Requirements |

| Quality Control | 100% Inspection |

| Features | Precise, Durable |

| Optional Processing Methods | Stamping/Diecasting/Casting/Lathe/Heat Treatment |

| Application Area | Electronics, Aerospace, Semiconductor, Automotive |

| Materials | Copper, Steel, Aluminum, Metal |

| Transport Package | Custom |

| Trademark | OEM |

| Origin | Xiamen, China |

| Production Capacity | 100,000 Pieces/Month |

Production Process:

- Material Selection: Choose the appropriate material, such as brass, copper, or steel, based on the specific requirements of the application.

- Tooling Design and Die Preparation: Design and fabricate custom stamping dies and tooling that ensure precise shaping, cutting, and forming of metal sleeves.

- Stamping: Using high-precision stamping machines, raw metal sheets are stamped to create the desired shape and dimensions of the sleeves. This step involves cutting, bending, and forming the metal.

- Secondary Operations: Additional processes like CNC machining, lathe operations, or centerless grinding may be used to refine the dimensions and features of the sleeves for improved accuracy and finish.

- Surface Treatment: The stamped sleeves undergo various surface treatments such as polishing, anodizing, or blackening to enhance durability, resistance to corrosion, and aesthetic appearance.

- Inspection and Quality Control: Rigorous inspection methods are employed to ensure the sleeves meet quality standards, including dimensional accuracy, surface finish, and functional performance.

- Customization and Final Adjustments: Custom modifications may be made according to customer specifications, including specific tolerances, finishes, or additional features.

- Packaging and Delivery: The finished metal stamping sleeves are carefully packaged to prevent damage during transportation and are delivered based on agreed timelines.

Optional Surface Treatments:

- Blackening: This process involves applying a protective black oxide layer to the metal surface, which helps improve corrosion resistance and enhances the part’s overall durability. Blackening is commonly used for parts that require a non-reflective finish and protection against environmental factors.

- Polishing: Polishing is used to achieve a smooth and shiny surface by removing any imperfections and burrs. This treatment not only enhances the appearance but also reduces friction and wear, making it ideal for components that require high surface smoothness and a glossy finish.

- Anodizing: Anodizing is an electrochemical process that forms a thick, durable oxide layer on the surface of metals, particularly aluminum. This treatment improves corrosion resistance, increases surface hardness, and allows for the addition of color dyes for aesthetic purposes. It is commonly used in industries where both functionality and appearance are crucial.

- Sandblasting: Sandblasting involves propelling abrasive materials at high velocity onto the surface of the metal, creating a textured, matte finish. This process is often used to prepare surfaces for coating, to clean parts, or to achieve a specific surface roughness that improves adhesion of paints or other coatings.

Our Factory:

We operate a comprehensive range of plants and equipment to ensure the highest quality production. Our facilities are equipped with 25 punch presses ranging from 25 tons to 300 tons, precision wire EDM machines, grinding equipment, welding and polishing tools, and ultrasonic cleaning systems.

In addition to our manufacturing capabilities, we offer a variety of metal plating processes to enhance the durability, appearance, and functionality of our metal stamping products. These include electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our state-of-the-art plating facilities ensure consistent finishes, corrosion resistance, and compliance with industry standards.

This combination of professional and automated production lines, advanced mechanical equipment, rigorous quality control measures, and high-quality plating processes ensures we deliver metal stamping products of the highest standard.

Reviews

There are no reviews yet.