Overview:

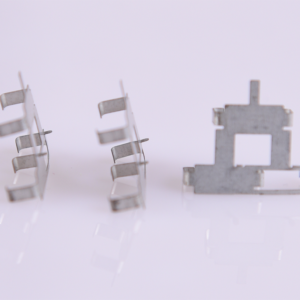

Metal stamping spring clips are essential components in car chargers, ensuring secure electrical connections and maintaining consistent contact for efficient power transfer. These clips are manufactured using high-precision stamping processes and are typically made from durable, conductive materials like stainless steel or beryllium copper to deliver excellent elasticity and corrosion resistance.

We specialize in OEM custom spring clips, providing tailored designs to meet your specific requirements, including dimensions, materials, and surface treatments. Enhance your car charger performance with our high-quality, cost-effective solutions. Contact us today to discuss your custom clips!

Details:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Size | Custom |

| Thickness | Custom |

| Materials | Zinc, Aluminum, Copper, Steel, Stainless Steel, Brass, Beryllium Copper, etc. |

| Surface Treatment | Electric Plating, Powder Coating, Sand Blasting, Lacquer |

| Process | Punching, Stamping, Bending, Riveting, etc. |

| Technology | Metal Stamping |

| OEM | Accept |

| Certification | ISO 9001:2008, IATF 16949 |

Production Process:

-

Raw Material Selection

– High-quality raw materials, such as stainless steel, aluminum, or beryllium copper, are carefully chosen for their strength, conductivity, and corrosion resistance. These materials are prepared in sheets or coils for processing.

-

Pressing and Cutting

– The raw materials are precision-pressed and cut into predefined shapes and sizes, forming the base pieces required for stamping.

-

Stamping and Bending

– Using high-speed stamping equipment, the materials are shaped into spring clip designs with precise dimensions. Bending operations are performed to achieve the necessary curvature and structure.

-

Welding and Joining

– If required, welding or other joining techniques are used to connect components, ensuring strength and integrity in the finished product.

-

Coating and Surface Treatment

– Clips undergo surface treatments such as electroplating, powder coating, or other finishes to enhance durability, corrosion resistance, and appearance.

-

Assembly and Quality Control (QC)

– The clips are assembled if needed, and rigorous quality checks are performed to ensure all components meet dimensional, structural, and functional standards.

-

Storage and Packaging

– Finished spring clips are safely stored and packaged to prevent damage during transportation, ensuring they arrive in pristine condition.

Why Choose Us?

-

Custom Solutions & OEM Services

– We offer sample provision, OEM services, and tailored suggestions to meet your specific needs, ensuring the best solution for your application.

-

High-Quality & Comprehensive Testing

– All products undergo rigorous quality control, including a minimum 72-hour salt spray test, and we provide additional secondary operations like drilling, plating, and heat treatment.

-

Efficient Assembly & Packaging

– We handle assembly through welding, installation, and custom packaging, ensuring products are delivered in optimal condition.

-

Competitive Pricing & On-Time Delivery

– Enjoy competitive pricing without compromising on quality, with flexible order sizes and reliable on-time delivery (10-20 days, depending on quantity).

Our Factory:

We operate a full spectrum of advanced facilities and equipment to guarantee top-tier production quality. Our manufacturing capabilities include 25 high-performance punch presses, ranging from 25 to 300 tons, as well as precision wire EDM machines, grinding tools, welding stations, polishing equipment, and ultrasonic cleaning systems.

To further enhance the durability, aesthetics, and performance of our metal stamping products, we offer a wide array of metal plating services. These include electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our cutting-edge plating facilities ensure consistent coating quality, superior corrosion resistance, and strict adherence to industry standards.

By combining state-of-the-art production lines, advanced mechanical equipment, and rigorous quality control protocols with our comprehensive plating options, we ensure the delivery of metal stamping products that meet the highest standards of excellence.

Reviews

There are no reviews yet.