Description:

OEM metal electrical terminals for automotive applications play a critical role in establishing secure and reliable connections within automotive electrical systems. These terminals are precision-manufactured using techniques such as crimping or soldering, ensuring a stable electrical flow between power sources and connected devices. Often arranged on modular, insulated terminal blocks, they can be tailored to meet specific requirements, including wire sizes, configurations, and performance standards. We provide fully customizable electrical terminals designed to your exact specifications, ensuring superior functionality and reliability for your automotive electrical systems.

Features:

| Specification | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Type | Terminal |

| Application | Connecting |

| Certification | ISO 9001, RoHS, IATF 16949 |

| Metal Material | Copper, Brass |

| Connection Range | 0.75mm² to 1.5mm² |

| Operating Temperature | -40°C to 105°C |

| Wire Compatibility | Compatible with standard automotive wires and cables. |

| Customization Options | Available in various sizes, configurations, and materials to meet specific needs. |

| Packaging Options | Available in bulk packaging or custom packaging solutions. |

| Durability | High resistance to vibration, moisture, and temperature extremes, ensuring long-lasting functionality. |

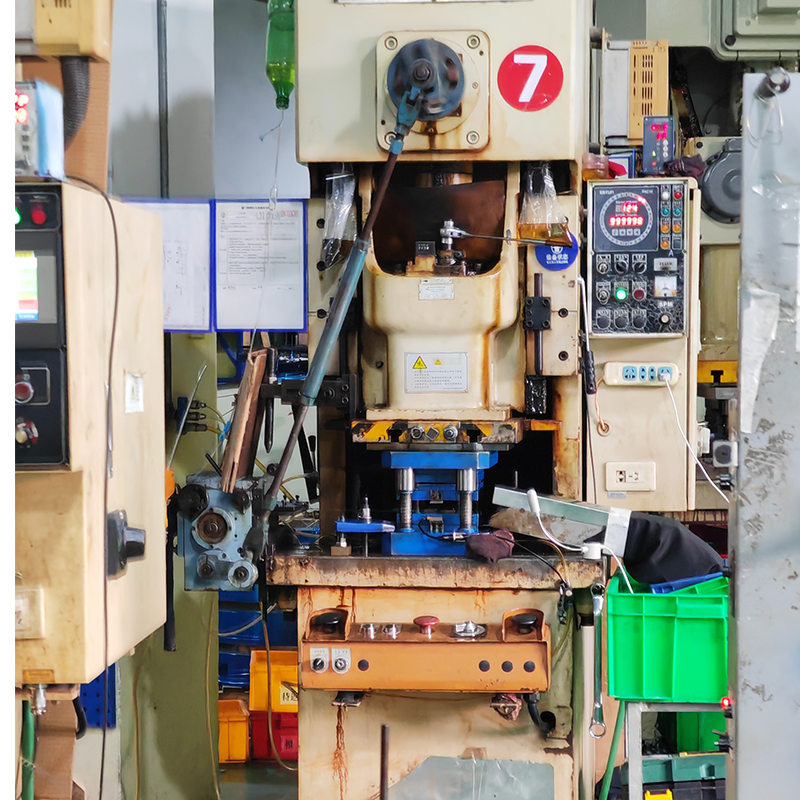

Quality Control:

The quality control process for metal electrical terminals used in automotive applications is meticulously designed to ensure optimal performance, durability, and compliance with industry standards. It begins with the inspection of incoming raw materials, such as copper and brass, to confirm their quality and consistency. Throughout production, dimensional accuracy is regularly checked to ensure the terminals meet strict specifications. After manufacturing, functional evaluations are carried out, including tensile strength testing of crimped connections and electrical conductivity assessments to guarantee reliable performance. Additionally, corrosion resistance is tested to verify the effectiveness of surface treatments like tin or nickel plating. Our factory employs advanced inspection tools, including coordinate measuring machines (CMM), Vickers hardness testers, projectors, and electrical testing systems, to thoroughly inspect every terminal. This comprehensive quality control process ensures that each terminal meets the highest standards of reliability and is fully suited for demanding automotive applications.

Surface Treatment Options:

-

Tin Plating

Tin plating is a highly effective surface treatment commonly used for electrical terminals, providing exceptional corrosion resistance and enhancing electrical conductivity. It is particularly suited for automotive applications that are exposed to moisture and other environmental factors, ensuring long-lasting performance in demanding conditions.

-

Nickel Plating

Nickel plating delivers superior corrosion resistance, increased wear resistance, and improved conductivity. It is frequently applied to automotive electrical terminals that require enhanced durability and protection against harsh environmental conditions, making it an ideal choice for long-term reliability.

-

Gold Plating

Gold plating is known for its excellent conductivity and high corrosion resistance, making it a preferred choice for applications that demand high performance and low-voltage reliability. It is commonly used in automotive parts where minimal electrical resistance and superior connection reliability are essential.

-

Silver Plating

Silver plating offers the highest electrical conductivity of any plating material, making it an optimal choice for automotive electrical terminals used in high-frequency or high-power applications. It also provides strong corrosion resistance, though it may require additional protection against tarnishing to maintain its performance over time.

Our Services:

Industry Expertise

With over two decades of experience in the spring manufacturing industry, we leverage our deep technical knowledge and industry insight to provide customized, high-performance solutions that meet the specific needs of our clients.

Sample Availability

We offer quick access to product samples within 7 days for your evaluation. Should the required tooling be available, we can provide these samples at no extra cost, ensuring you can assess the quality and fit before committing to production.

Rapid Turnaround

Our typical lead time is within 10 days, allowing us to deliver products quickly and efficiently to align with your production schedules and project timelines.

Commitment to Excellence

We are dedicated to offering competitive pricing, outstanding customer service, and unwavering product quality. Our business philosophy centers on delivering value and ensuring our clients’ success through reliable solutions and exceptional support.

Reviews

There are no reviews yet.