Description:

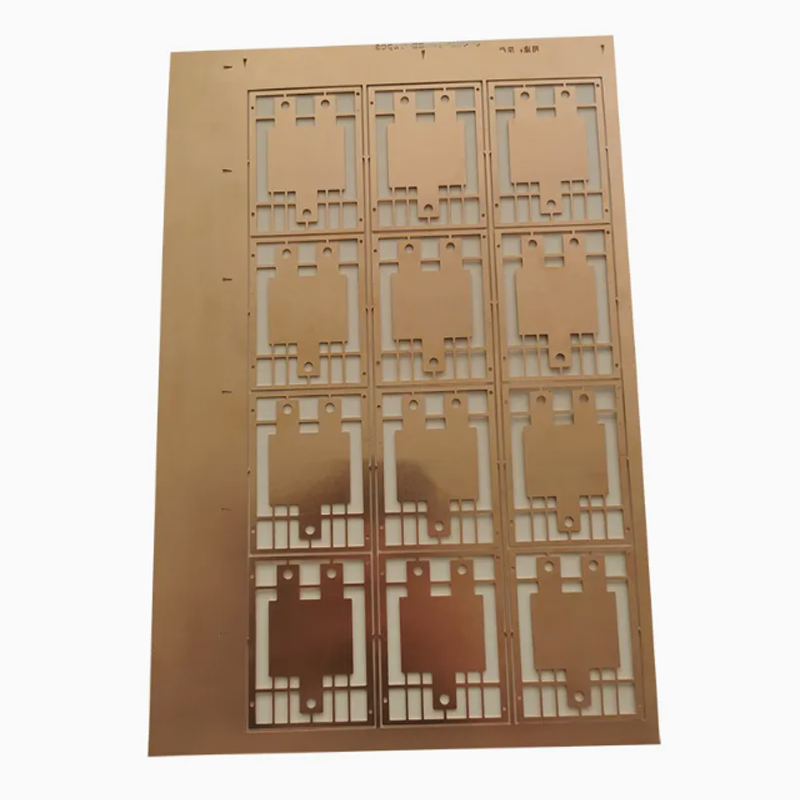

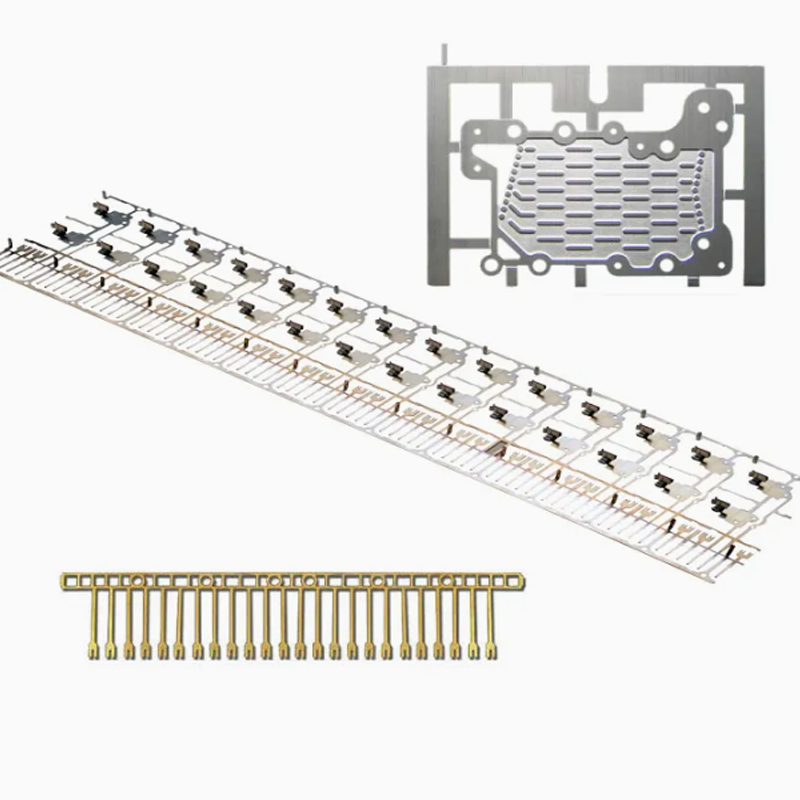

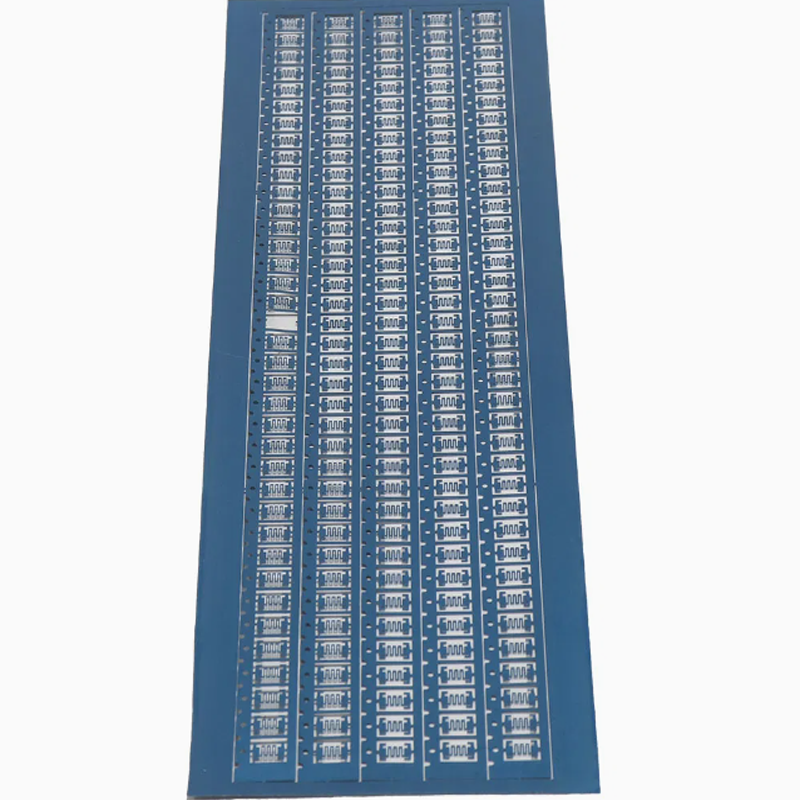

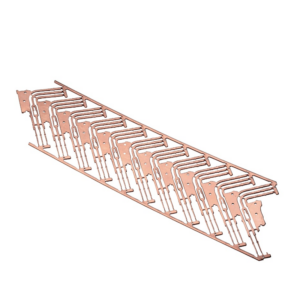

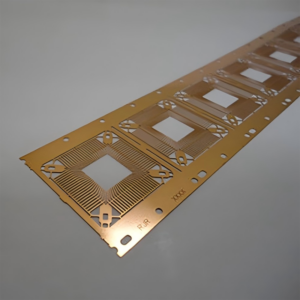

OEM Metal LED Lead Frames are precision components used to connect LED chips to circuit boards, ensuring reliable electrical and thermal performance. Made from high-quality materials like stainless steel, copper alloy, and phosphor bronze, these lead frames are manufactured through metal stamping and precision forming, often with surface treatments such as electroplating for enhanced durability and solderability. They are ideal for applications in lighting, automotive, and consumer electronics, offering superior performance and longevity. Our factory provides OEM customization services, including material selection, surface treatments, and tailored manufacturing processes to meet your specific requirements.

Characteristics:

| Attribute | Details |

| Material | Stainless Steel |

| Brand Name | OEM |

| Service | Customized OEM |

| Application | Electrical |

| Color | Customized Color |

| Thickness | Custom |

| MOQ | Small Orders Accepted |

| Place of Origin | Xiamen, China |

| Package | Custom |

| Micro Machining | Yes |

| Process | Metal Stamping |

| Features | No Burrs, No Broken Points, No Plugging Holes |

| After-Sale Service | Yes |

| Transport Package | As Per Your Requirement |

| Size | Custom Size |

| Trademark | OEM |

| Production Capacity | 100,000 Pieces/Year |

Production Process:

- Material Preparation: The first step is to source and prepare the base material, usually stainless steel or other suitable metals, which are cut to the required dimensions.

- Metal Stamping: Using high-precision stamping machines, the metal is stamped into the desired lead frame shape. This step may involve progressive or fine blanking dies to achieve intricate designs.

- Forming and Shaping: The stamped metal parts are then formed into the precise shape and structure necessary for the LED application, which may include bending or further shaping.

- Surface Treatment: The lead frame undergoes surface treatment processes like electroplating, coating, or cleaning to enhance its performance, durability, and aesthetic appeal.

- Assembly: The final step involves the assembly of the lead frame, which may include connecting it to the semiconductor or integrating it with other components as needed for the end product.

Surface Treatment options:

-

Electroplating

Electroplating involves coating the metal lead frame with a thin layer of another metal, such as gold, silver, or nickel, to improve corrosion resistance, conductivity, and overall durability.

-

Tin Plating

Tin plating is commonly used to prevent oxidation and enhance solderability. This process involves applying a layer of tin over the metal surface to provide excellent electrical performance and protection.

-

Nickel Plating

Nickel plating enhances the lead frame’s resistance to wear, corrosion, and heat. This treatment is particularly beneficial for improving longevity and maintaining performance in harsh environments.

-

Gold Plating

Gold plating is used for high-end applications, providing superior conductivity and corrosion resistance. This is especially important in precision electronics where long-term reliability is critical.

-

Passivation

Passivation is a chemical treatment that creates a protective oxide layer on stainless steel or other metals to enhance corrosion resistance and reduce the likelihood of surface contamination.

-

Phosphating

Phosphating involves applying a phosphate coating to the lead frame. This treatment improves corrosion resistance and acts as a base for further coatings or as a lubricant in the manufacturing process.

Why Choose Us?

– Cost-effective tooling, eliminating the need for expensive dies or molds

– Capable of fabricating thin metals (T=0.02-1.2 mm)

– No secondary processes required, ensuring design specifications are met

– Exceptional precision

– Versatile design options for apertures, shapes, and bar configurations

– Burr-free and stress-free production process

– Rapid prototype development to meet project timelines

– High-volume production capacity

Reviews

There are no reviews yet.