Description:

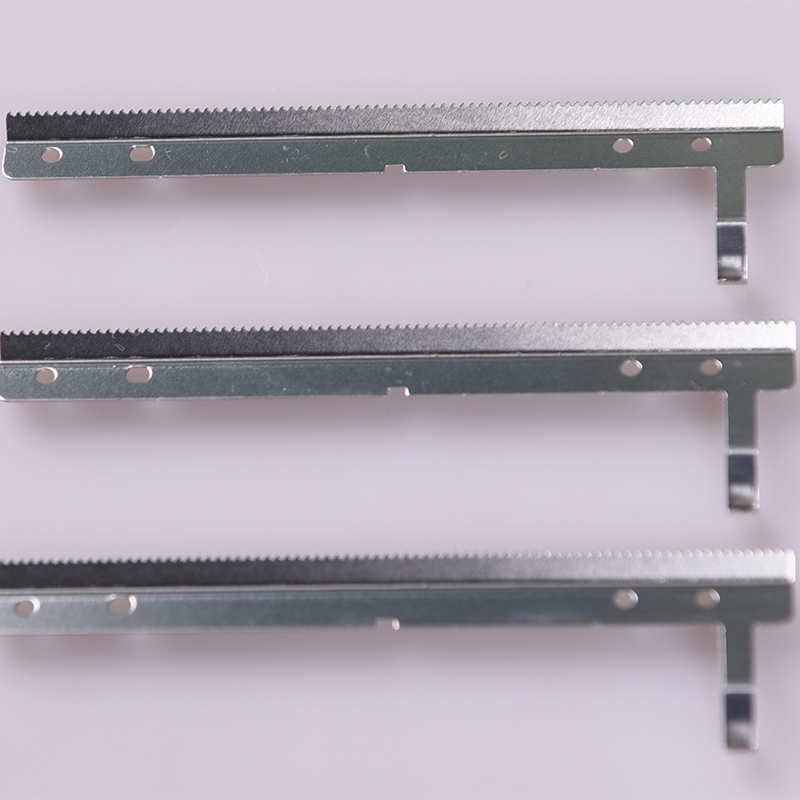

OEM metal stamped brackets for POS printers are precision-engineered components designed to support and secure various parts within point-of-sale (POS) printer systems. These brackets are typically made from high-quality metals such as stainless steel, carbon steel, aluminum, or brass, ensuring durability and long-lasting performance. The primary function of these brackets is to provide reliable structural support, allowing for the smooth and efficient operation of the printer. They are designed to be corrosion-resistant, lightweight, and able to withstand the demands of continuous use in high-traffic environments.

Our one-stop service includes custom design, precision stamping, material selection, surface treatment options (such as powder coating or plating), and assembly services, all tailored to meet your specific requirements. With a focus on quality, efficiency, and fast delivery, we ensure that our metal stamped brackets for POS printers meet the highest industry standards, optimizing both functionality and performance.

Details:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Standard | ROHS, ISO9001 |

| Size | Custom |

| Services | OEM |

| Material | Spring Steel, Galvanized Steel, Steel, Stainless Steel, Aluminum, etc. |

| Surface Treatment | Galvanized, Painting, Powder Coating, Plating, Polishing |

| Process | Stamping, Punching, Bending |

| Color | Custom |

| Application | POS Printer |

| Sample | Available |

Production Process:

- Material Selection: The process begins with selecting the appropriate material, such as spring steel, galvanized steel, stainless steel, or aluminum, based on the specific requirements of the POS printer.

- Design and Engineering: Custom designs are created using CAD (Computer-Aided Design) software. The designs are then reviewed for accuracy, fit, and functionality before proceeding to production.

- Stamping and Punching: The selected material is loaded into a high-precision stamping press. The material is stamped or punched into the desired shape using progressive dies, ensuring consistent size and shape for each bracket.

- Bending: After stamping, the brackets undergo a bending process to achieve the necessary angles and shapes that allow them to fit securely into the POS printer assembly.

- Surface Treatment: To enhance the strength, appearance, and corrosion resistance, the metal brackets are subjected to various surface treatments. These may include galvanizing, painting, powder coating, plating, or polishing, depending on the required finish.

- Quality Control and Inspection: Each bracket undergoes thorough quality control checks, including dimensional inspection, material testing, and visual inspection to ensure that they meet strict specifications and are free from defects.

- Packaging and Shipping: After passing quality inspections, the finished brackets are carefully packaged and prepared for shipment, ensuring safe delivery to customers in a timely manner.

Our Advantages:

-

Tailored OEM & Assembly Solutions

With over two decades of experience, we specialize in delivering custom OEM solutions and comprehensive assembly services, tailored to meet the unique needs of each client.

-

End-to-End Service Offering

We provide a complete range of manufacturing capabilities, including precision stamping, CNC machining, lathe and milling operations, spring production, fasteners, shafts, and other critical components, all under one roof.

-

Certified and Trusted Supplier

As a reliable second-tier supplier, we have successfully passed rigorous factory audits and hold industry certifications such as RoHS and HE compliance, ensuring the highest standards in product quality and environmental responsibility.

-

Commitment to Excellence in Quality Management

Our facilities are certified to ISO 9001:2015 and IATF 16949 standards, underscoring our commitment to maintaining superior quality control and delivering products that meet the most demanding specifications.

Our Factory:

We operate a state-of-the-art manufacturing facility equipped with advanced equipment, including 25 punch presses ranging from 25 to 300 tons, precision wire EDM machines, grinding machinery, welding and polishing tools, and ultrasonic cleaning systems, ensuring optimal production quality. In addition to our robust manufacturing capabilities, we offer a range of metal plating services—such as electroplating, zinc plating, nickel plating, chrome plating, and anodizing—designed to enhance the durability, aesthetics, and functionality of our metal stamping products. Our cutting-edge plating facilities guarantee consistent finishes, superior corrosion resistance, and compliance with industry standards. This integration of automated production lines, advanced machinery, stringent quality control protocols, and high-quality plating ensures the delivery of precision-engineered stamping products that meet the highest industry benchmarks.

Reviews

There are no reviews yet.