Overview:

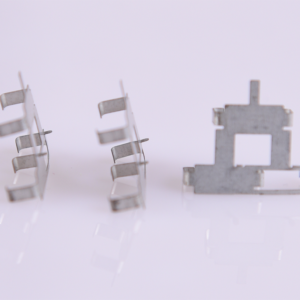

Our factory specializes in high-quality custom metal stampings and assemblies, with a focus on precision-engineered metal brackets designed to meet the most demanding application requirements. Utilizing advanced progressive stamping, laser cutting, and welding techniques, we offer a range of customizable options in materials, finishes, and design configurations to suit various industrial needs. Our metal brackets are crafted to ensure durability, functionality, and precision, making them ideal for automotive, construction, and electronics applications.

Details:

| Attribute | Details |

| Processing Type | Shaping Metal |

| Material | Stainless Steel |

| Mould | Simple Single Process Dies |

| Surface Processing | Electroplating |

| Tolerances | 0.01mm |

| Customization | Available (Customizable) |

| Transport Package | Carton, Pallet, Wooden Box |

| Specification | Custom |

| Trademark | OEM |

| Origin | China |

| Production Capacity | 300,000 PCS/Month |

Production Process:

-

Designing the Drawing

The process begins with the creation of precise technical drawings, detailing the dimensions, features, and specifications of the metal bracket.

-

Material Selection

Custom materials are chosen based on the product’s requirements, such as stainless steel, ensuring optimal performance and durability.

-

Mold Creation

Custom molds are fabricated to match the design specifications, enabling efficient production of high-precision metal components.

-

Stamping

The metal is stamped using high-precision machines, such as progressive stamping presses, to form the basic shape of the bracket.

-

Cutting

After stamping, the metal is carefully cut to size to achieve the final shape and dimensions required for the bracket.

-

Polishing

The stamped parts undergo a polishing process to smooth out any rough edges and improve surface finish quality.

-

Surface Treatment

The brackets are subjected to surface treatments such as electroplating or powder coating to enhance corrosion resistance and ensure long-lasting performance.

-

Quality Inspection

A comprehensive inspection is conducted to verify the brackets meet all quality standards and dimensional requirements.

-

Packaging

Finally, the finished brackets are carefully packaged for safe transport, ensuring they arrive at the customer’s location in perfect condition.

Surface Treatment Options:

-

Electroplating

Electroplating involves coating the metal bracket with a thin layer of metal (such as zinc or nickel) to enhance corrosion resistance, improve durability, and provide a sleek finish.

-

Powder Coating

Powder coating applies a durable, colored finish to the bracket, offering excellent resistance to wear, scratches, and environmental factors. It also provides a uniform, attractive surface finish.

-

Galvanizing

Hot-dip galvanizing involves coating the bracket with a layer of zinc to prevent rust and corrosion, ensuring long-lasting protection in harsh environments.

-

Anodizing

Anodizing is an electrochemical process that thickens the natural oxide layer on aluminum brackets, increasing their corrosion resistance and providing a durable, scratch-resistant finish. It also allows for color customization.

These surface treatments are chosen based on the specific needs of the application, ensuring optimal performance and longevity.

Why Choose Us?

-

Tailored OEM Solutions

We specialize in providing fully customized OEM services, adapting our products to meet your exact specifications and requirements, ensuring a perfect fit for your application.

-

Rapid Delivery

We are committed to fast turnaround times, offering expedited production and timely delivery to meet tight schedules without compromising quality.

-

Rigorous Quality Control

Our comprehensive quality control process guarantees that every product meets the highest standards. We are certified under ISO 9001, IATF 16949, and SGS, demonstrating our commitment to excellence and reliability.

-

24/7 Customer Support

Our customer service team is available around the clock to provide prompt assistance, ensuring seamless communication and immediate support for all inquiries.

-

Professional Engineering Expertise

With years of experience, our skilled engineering team is equipped to handle complex design challenges and deliver optimal solutions, ensuring high-quality, functional products.

-

Efficient Communication

We prioritize clear, efficient communication with our clients, offering professional and responsive support throughout the entire project lifecycle to ensure smooth collaboration and successful outcomes.

Reviews

There are no reviews yet.