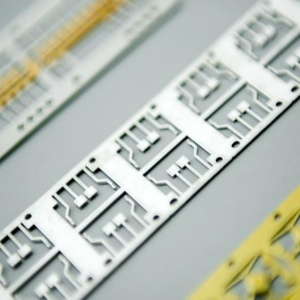

OEM Precision Durable Stainless Steel Frame Laser Cutting Services

Characteristics:

– Place of Origin: Xiamen, China

– Model Number: OEM/ODM

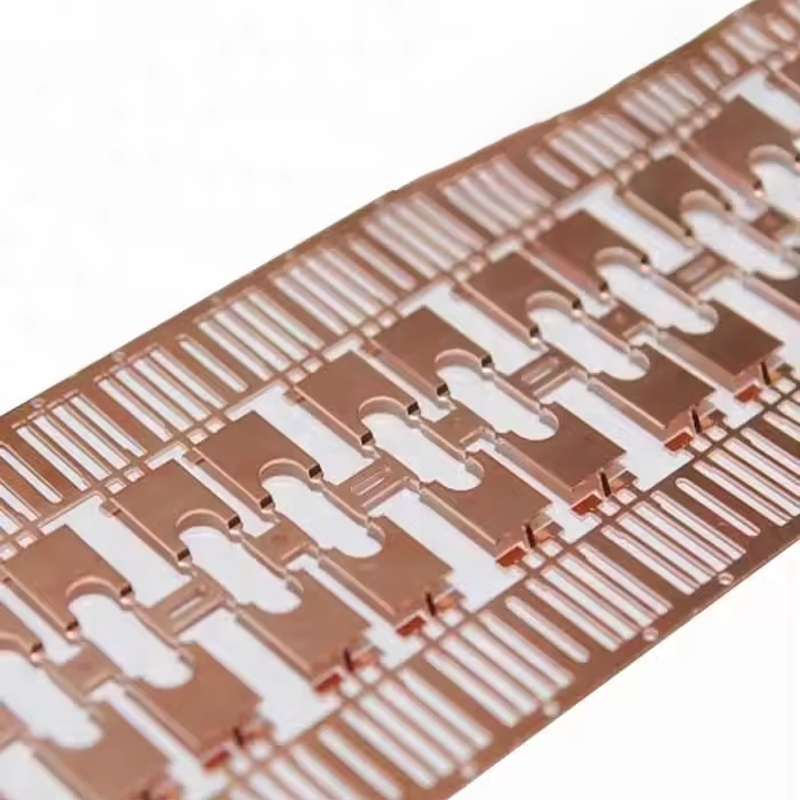

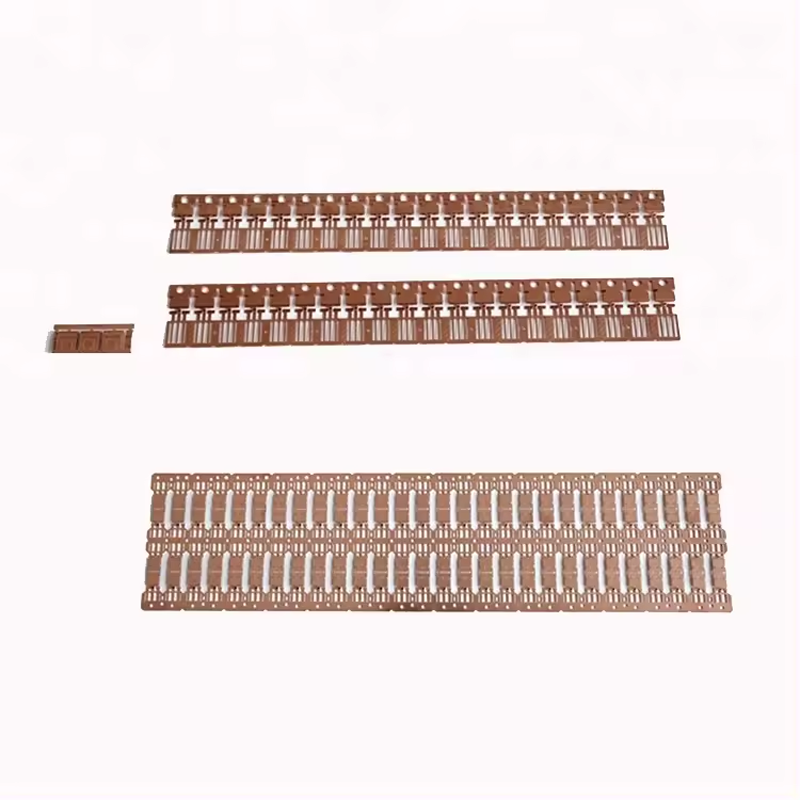

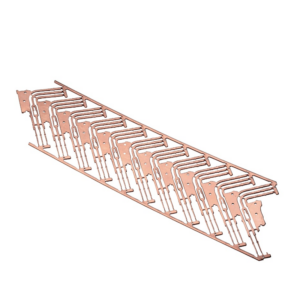

– Material: Aluminum, stainless steel, copper, brass, galvanized steel

– Application: Appliance, Auto, Building, Capital equipment, and Home

– Process: Laser Cutting, Bending, Stamping, Welding, Riveting, Powder Coating, Packaging

– Surface Treatment: Powder Coating, Anodizing, Polishing, Zinc Plating, Nickel Plating

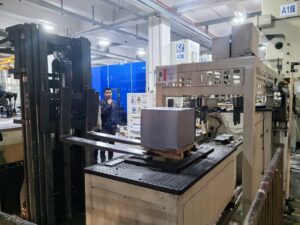

– Packing: Plastic Bag + Carton + Pallet

– Service: Design and Customization

– Drawing Format: 2D/3D/CAD/DWG/STEP/PDF/IGS

Surface Treatment Options:

Stainless Steel:

– Polishing

– Passivation

– Sandblasting

– Laser Engraving

– Black Oxide Finish

– Electrophoretic Black Coating

Steel:

– Zinc Plating

– Black Oxide Finish

– Nickel Plating

– Chrome Plating

– Powder Coating

– Heat Treatment

Aluminum:

– Clear Anodizing

– Color Anodizing

– Sandblast Anodizing

– Brushing

– Polishing

The Production process of Stainless Steel Frame:

- Material Preparation:

Stainless steel sheets are inspected for quality and compatibility with laser cutting processes. Any imperfections or irregularities are addressed to ensure optimal cutting results.

- CAD Design and Programming:

Detailed CAD designs are created based on client specifications. These designs are then translated into machine-readable instructions for the laser cutting equipment.

- Laser Cutting:

Utilizing advanced laser cutting technology, the stainless steel sheets are precisely cut according to the CAD designs. The laser beam melts, burns, or vaporizes the material along the programmed cutting path, resulting in clean and accurate cuts.

- Quality Inspection:

Each cut stainless steel frame undergoes rigorous quality inspection to ensure dimensional accuracy, edge smoothness, and overall quality. Any deviations or defects are identified and addressed promptly.

- Finishing Touches:

After cutting, the stainless steel frames may undergo additional processes such as deburring, edge smoothing, or surface treatments to meet specific client requirements and enhance aesthetic appeal.

- Packaging and Shipping:

Once the production process is complete and quality standards are met, the finished stainless steel frames are carefully packaged to prevent damage during transit and shipped to the client’s designated location.

About Us:

With over 20 years of expertise in custom precision sheet metal fabrication services, we are a leading manufacturing company dedicated to bringing your product ideas to life. From meter boxes to battery cabinets and various sheet metal parts, our products have been exported to the US, Australia, Spain, Israel, Germany, and other countries. Feel free to follow us and get in touch to turn your concepts into reality. Contact us today to send inquiries and discuss your project requirements.

-300x300.png)

Reviews

There are no reviews yet.