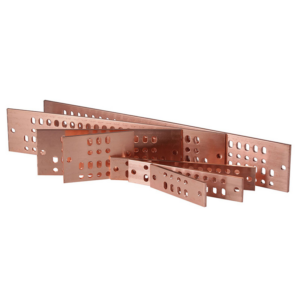

Overview:

Precision Stainless Steel 304 Stamped Sleeves are high-quality components manufactured using the deep drawing process. These sleeves are crafted from durable 304 stainless steel, known for its excellent corrosion resistance and strength. As a trusted manufacturer and supplier, Topmetalstamping provide these precision components for a wide range of industries, including automotive, electronics, and aerospace.We offer a one-stop service for all your stamping needs, including OEM solutions tailored to your specifications. Contact us today for more information or to discuss your requirements!

Features:

| Attribute | Details |

| Type | Cold Stamping |

| Processing Type | Deep Drawing |

| Material | Stainless Steel |

| Mould | Simple Single Process Dies |

| Surface Processing | Electroplating |

| Industry | Various Industries |

| Tolerances | 0.2mm |

| Customized | Yes |

| Standard | ISO9001, IATF16949 |

| Trademark | OEM |

| Transport Package | Custom |

| Size | Custom |

| Origin | Xiamen, China |

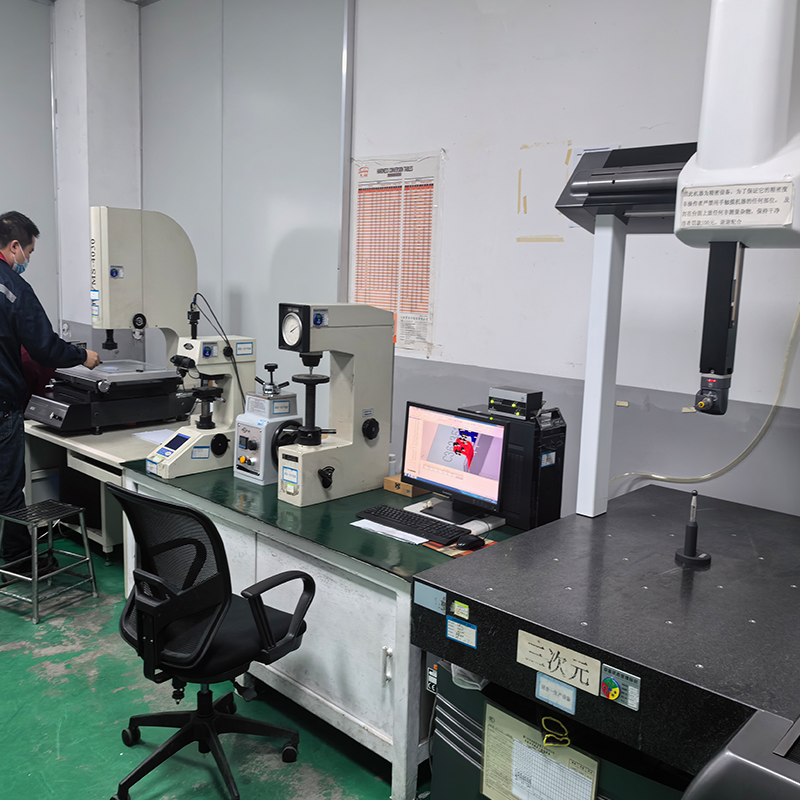

Quality Control Process:

The quality control process for Stainless Steel 304 Stamped Sleeves includes several critical steps to ensure precision and reliability. Initially, raw material inspection is conducted to verify the material’s composition and quality using spectrometers. During production, dimensional accuracy is measured using coordinate measuring machines (CMM) and calipers. Surface integrity is checked through visual inspection and surface roughness testing with specialized equipment. After stamping, the parts undergo functional testing to ensure they meet the required mechanical properties, such as tensile strength and flexibility, using a universal testing machine (UTM). Finally, electroplating thickness is verified with X-ray fluorescence (XRF) equipment. These stringent quality checks, combined with advanced testing tools, ensure the final product meets the highest industry standards.

Why Choose Us?

-

Advanced Research & Development Capabilities

Our specialized R&D team consistently drives innovations in manufacturing techniques, product performance, and cost optimization, positioning us as leaders in industry advancements.

-

End-to-End Tooling & Die Design

We handle all tooling and die design processes in-house, maintaining full control over quality, precision, and production efficiency from concept to final output.

-

Commitment to Superior Quality Assurance

With ISO 9001 and IATF 16949 certifications, we implement rigorous quality assurance systems to ensure every product adheres to the highest standards of reliability and performance throughout its entire lifecycle.

-

Comprehensive Product Inspections

All products undergo a thorough 100% inspection prior to shipment to guarantee they meet stringent specifications and offer exceptional durability and functionality.

-

Dependable, On-Time Delivery

We prioritize on-time delivery, offering expedited production for urgent orders, ensuring our clients consistently receive their products as promised, without delays.

Factory Show:

Our production facility is fully equipped with a wide range of advanced machinery to ensure exceptional manufacturing quality. We operate 25 punch presses with capacities from 25 to 300 tons, precision wire EDM machines, grinding systems, welding and polishing tools, and ultrasonic cleaning equipment.

To further enhance the performance, appearance, and longevity of our metal stamping products, we offer various plating services, including electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our state-of-the-art plating operations guarantee uniform finishes, superior corrosion resistance, and strict adherence to industry standards.

By combining automated production lines, cutting-edge machinery, stringent quality control practices, and advanced plating techniques, we are committed to delivering metal stamping components that meet the highest standards of quality and reliability.

Reviews

There are no reviews yet.