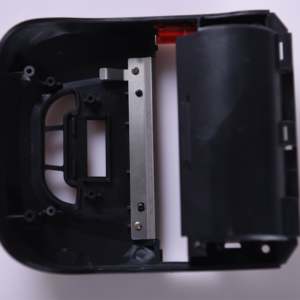

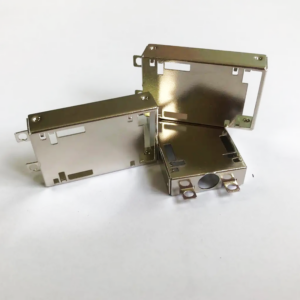

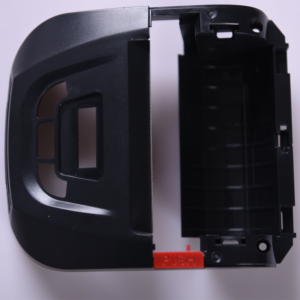

OEM Shield Case Galvanized Aluminum Sheet Metal Stamping Parts

A Shield Case Galvanized Aluminum is a protective enclosure crafted from aluminum, enhanced through metal stamping and coated with a layer of zinc for superior corrosion resistance and durability. The metal stamping process precisely shapes the aluminum, ensuring consistency and structural integrity. Following stamping, the aluminum component undergoes galvanization, where it is immersed in a bath of molten zinc, forming a metallurgic bond that shields the surface from environmental damage. This combination of metal stamping and galvanization ensures a robust, long-lasting protective case.

We offer comprehensive OEM services to meet your specific needs. Our OEM services allow you to customize the shield cases with your brand’s specifications, including size, shape, and additional features.

Basic Information:

Tolerances and Customization:

– Tolerances: Strict adherence to +/- 0.02mm tolerances for precise dimensions.

– Customized Service: Offering tailored solutions with +/- 0.01mm tolerances to meet specific requirements.

Quality Control and Shipment:

– Quality Control: Conducting thorough inspections to ensure product quality before shipping.

– Shipment Terms: Flexible shipping options including express, air freight, and sea freight.

Certifications and Documentation:

– Certificates: Holding ISO9001:2015, IATF16949, RoHS, and Reach certifications.

– Drawing Format: Accepting various drawing formats for ease of communication.

Transport Package and Production Capacity:

– Transport Package: Packaging products securely for safe delivery.

– Specification: Standardizing dimensions to 32*32*12 for consistency.

– Trademark and Origin: Branded as “SX” and originating from Xiamen, China.

– Production Capacity: Capable of producing up to 10,000 units to meet demand.

Surface Finishes for Metal Components:

- Plating:

Includes zinc, nickel, chrome, and tin plating, offering enhanced corrosion resistance and aesthetic appeal.

- Powder Coating:

Applied as a dry powder and cured to create a durable, decorative finish with various color options.

- Anodizing:

Creates a protective oxide layer on metal surfaces, commonly used for aluminum components to improve corrosion resistance and durability.

- Paint Coating:

Liquid paint applied to metal surfaces for aesthetic enhancement and corrosion protection, offering versatility in color choices.

Industry Applications:

- Automotive Industry:

– Shield Case Galvanized Aluminum Sheets are commonly used in the automotive industry to manufacture various components such as engine covers, heat shields, and underbody protection due to their excellent corrosion resistance and durability.

- Electronics Industry:

– In the electronics industry, Shield Case Galvanized Aluminum Sheets are utilized to produce housings and enclosures for electronic devices such as control panels, circuit boards, and power supplies, providing robust protection against environmental factors.

- Construction Industry:

– Within the construction sector, Shield Case Galvanized Aluminum Sheets find applications in roofing, siding, and structural components where corrosion resistance and longevity are essential, ensuring long-lasting performance in diverse weather conditions.

- Industrial Machinery:

– Shield Case Galvanized Aluminum Sheets are integral in the manufacturing of industrial machinery components such as casings, panels, and guards, offering reliable protection against corrosion, abrasion, and mechanical damage, thus extending the lifespan of equipment.

Factory Show:

Reviews

There are no reviews yet.