Overview:

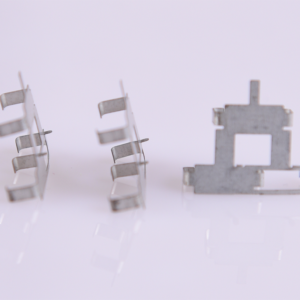

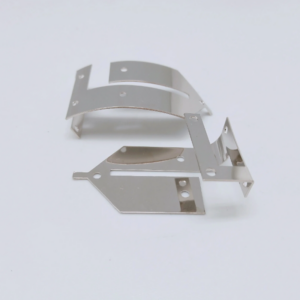

SUS304 stainless steel sheet metal brackets are high-performance components made from SUS304 stainless steel, known for its excellent corrosion resistance, durability, and versatility. These brackets are primarily manufactured through precision metal stamping and bending processes, which ensure accurate dimensions and a smooth finish. Our factory offers OEM services, providing custom solutions for a wide range of sizes, designs, and surface treatments, such as powder coating, anodizing, and plating. These stainless steel brackets are widely used in various industries, including automotive, electronics, construction, and machinery, for mounting, supporting, or securing components in demanding environments.

Features:

– Place of Origin: Xiamen, China

– Brand Name: OEM

– Certificate: ISO9001 / IATF16949

– Surface Treatment: Nickel Plating / Chrome Gold Plated

– Thickness: 0.1 – 12.0mm (as required)

– Shape: OEM

– Material: Brass, Copper, Carbon Steel, Stainless Steel

– Inspection: 100% Inspection Before Delivery

Advantages of Stainless Steel Sheet Metal Brackets:

– High Corrosion Resistance: SUS304 stainless steel is highly resistant to rust and corrosion, making it perfect for use in demanding environments and applications exposed to moisture.

– Exceptional Durability: Known for its outstanding strength, SUS304 ensures long-term durability and reliability, even under heavy load conditions.

– Customization Flexibility: With its ability to be precisely shaped and sized, SUS304 allows for tailored solutions, making it versatile for a wide range of industries and applications.

– Premium Aesthetic Quality: The smooth, polished surface of SUS304 stainless steel provides an attractive, professional finish, ideal for both functional and aesthetic requirements.

Production Process:

- Material Selection: High-quality SUS304 stainless steel sheets are chosen for their excellent corrosion resistance, durability, and strength, ensuring suitability for a variety of applications.

- Cutting and Shearing: The stainless steel sheets are cut to the required size and shape using advanced cutting machines or laser shears, ensuring precise dimensions and minimal material waste.

- Forming and Bending: The cut metal pieces are then shaped using press brakes or other bending machines to form the bracket’s desired contours and angles.

- Surface Treatment: The brackets undergo surface treatments such as nickel plating, chrome plating, or polishing to enhance corrosion resistance, improve appearance, and ensure durability under various conditions.

- Quality Control: Rigorous inspections are conducted throughout the production process, including dimensional checks, surface quality assessments, and functional tests, to ensure the brackets meet all required specifications and industry standards.

- Packaging and Delivery: After passing final inspections, the brackets are carefully packaged to prevent damage during transport and delivered to customers in a timely manner, ready for use in their respective applications.

Surface Treatment Options:

- Nickel Plating: A thin layer of nickel is electroplated onto the surface, offering improved corrosion resistance, enhanced durability, and a polished finish.

- Chrome Plating: A chrome coating is applied to provide a shiny, durable finish with excellent corrosion resistance and wear protection, ideal for applications exposed to harsh environments.

- Chrome Gold Plating: A combination of chrome plating with a gold tint, providing an attractive appearance along with corrosion resistance, commonly used for decorative and high-end applications.

- Polishing: A mechanical polishing process that results in a smooth, shiny surface finish, reducing friction and improving the overall aesthetic appeal of the brackets.

Our Factory:

Our manufacturing facility is equipped with a wide array of advanced equipment, including 25 punch presses (ranging from 25 to 300 tons), precision wire EDM machines, grinding equipment, welding and polishing tools, and ultrasonic cleaning systems, ensuring top-tier production quality. We also offer a range of metal plating options, such as electroplating, zinc plating, nickel plating, chrome plating, and anodizing, to enhance the durability, appearance, and functionality of our stamped products. With state-of-the-art plating facilities and stringent quality control protocols, we guarantee consistent finishes, corrosion resistance, and adherence to industry standards. This combination of cutting-edge technology, professional-grade equipment, and robust quality assurance processes ensures that our metal stamping products meet the highest levels of performance and reliability.

Reviews

There are no reviews yet.