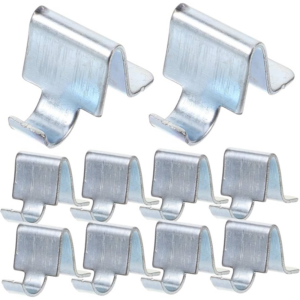

Personalized Supplying Nickel Plated Spring Steel Metal Stamping Contact Clips

Description:

Nickel-Plated Spring Steel Metal Stamping Contact Clips are precision-engineered components crafted from high-strength spring steel and coated with a nickel layer. These clips are designed through metal stamping processes to achieve specific shapes and mechanical properties, making them ideal for applications requiring reliable electrical contact and resilience. The nickel plating enhances their resistance to corrosion, wear, and tarnish, ensuring long-lasting performance and improved conductivity. They are commonly used in various electrical and electronic assemblies where durability and precise contact are essential.

Key Features:

- Premium Metal Construction:

Crafted from high-quality metal materials, our product ensures exceptional durability, lightweight portability, and ease of handling, catering to your on-the-go needs.

- Universal Compatibility:

Designed to be compatible with 18650 BC-1719 spring steel 18650 battery bases, our product offers versatile usage across various battery configurations.

- Compact and Portable Design:

Compact and lightweight, our product is easy to transport, featuring 10 battery clips for ample storage capacity while maintaining a small footprint.

- Enhanced Durability and Conductivity:

Engineered for superior durability, aesthetics, and conductivity, our product provides optimal protection for batteries and minimizes power wastage, ensuring efficient energy usage.

- Exceptional Electrical Conductivity:

Constructed from premium metal materials, our product boasts excellent electrical conductivity, facilitating seamless power transfer and maximizing performance.

Specifications:

Material: Iron with Nickel Plating

Dimensions: 0.83 x 0.63 inches / 2.1 x 1.6 cm

Color: As depicted in the image

Production Process for Nickel-Plated Spring Steel Metal Stamping Contact Clips:

- Material Selection:

– Choose high-quality spring steel suitable for stamping and nickel plating, ensuring durability and performance.

- Sheet Metal Cutting:

– Cut the selected steel sheets into the required sizes and shapes, preparing them for stamping.

- Stamping:

– Use precision stamping dies to shape the cut steel sheets into contact clip forms. This step involves applying high pressure to create the desired geometry and features of the clips.

- Heat Treatment:

– Subject the stamped clips to heat treatment processes, such as annealing or tempering, to enhance their hardness and elasticity.

- Nickel Plating:

– Apply a nickel plating to the heat-treated clips to improve corrosion resistance and provide a smooth, conductive surface. This involves electroplating the clips with a nickel layer.

- Inspection and Quality Control:

– Conduct thorough inspections to ensure that the clips meet the required specifications and quality standards. This includes checking for dimensional accuracy, plating thickness, and overall integrity.

- Assembly and Final Testing:

– Assemble the clips if required and perform final tests to verify functionality and performance.

- Packaging:

– Package the finished contact clips in a manner that protects them during shipping and handling, ensuring they reach customers in optimal condition.

Reviews

There are no reviews yet.