Description:

A bracket is a metal component used to support, secure, or mount other objects in place. These versatile parts are commonly made through precision stamping or metal forming processes, which ensure the accuracy and strength needed for a wide range of applications. Brackets are typically crafted from durable materials like stainless steel, carbon steel, aluminum, or brass, selected for their strength, corrosion resistance, and suitability for the specific use case.

At Topmetalstamping, we are committed to delivering high-quality metal brackets through advanced manufacturing techniques. Our ISO:14001, ISO:9001, and IATF16949 certified facilities utilize the latest technology, including EDM, CAD/CAM, and CNC machining, to produce precision components that meet the highest industry standards. Our experienced die makers and stringent quality control measures ensure that every bracket is manufactured to exact specifications, setting us apart from the competition.

Features:

| Item | Details |

| Mould | Multistep Progressive Dies |

| Process | Forming Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.03mm or Above |

| Raw Material | Iron, Stainless Steel, Brass, Aluminum (Al), Copper, etc. |

| Thickness | As Per The Customer’s Technical Drawing or Samples |

| Certificates | IATF16949:2016, ISO9001:2015, RoHS, REACH |

| Delivery Method | By Sea, By Air, or By Express Service |

| Packaging Details | According to The Client’s Request |

| Technology | 20 Years Experience |

| Accuracy | +/- 0.01mm |

| Specification | As per the Customer’s Technical Drawing or Samples |

| Trademark | OEM |

| Origin | Xiamen, China |

| Production Capacity | 100,000 Pieces/Per Day |

Quality Control Process:

Our inspection process for precision brackets is meticulously designed to ensure the highest standards of quality throughout every stage of production. It begins with raw material inspection (IQC), where materials are thoroughly evaluated for compliance with specifications. This is followed by first article confirmation (IPQC) and site inspection (IPQC) to verify the accuracy and quality of the initial production batches. Final inspection (FQC) ensures that all parts meet the required tolerances and specifications, and a comprehensive delivery inspection (QA) guarantees that the finished products are ready for shipment. Our quality control department utilizes an array of advanced testing instruments, including a raw material chemical composition spectrograph, X-ray coating thickness tester, sclerometer, salt spray tester, micrometers, calipers, thread ring gauge, dial gauges, manometers, angle gauges, and a fully automated vision tester, to uphold the highest standards of precision and reliability.

Surface treatments:

- Zinc Plating: Provides excellent corrosion resistance, ideal for protecting brackets in harsh environments.

- Nickel Plating: Offers superior hardness, wear resistance, and a smooth, aesthetically pleasing finish.

- Chrome Plating: Provides a bright, reflective finish with exceptional resistance to corrosion, abrasion, and chemicals.

- Tin Plating: Ensures excellent solderability and corrosion resistance, ideal for electronics and sensitive applications.

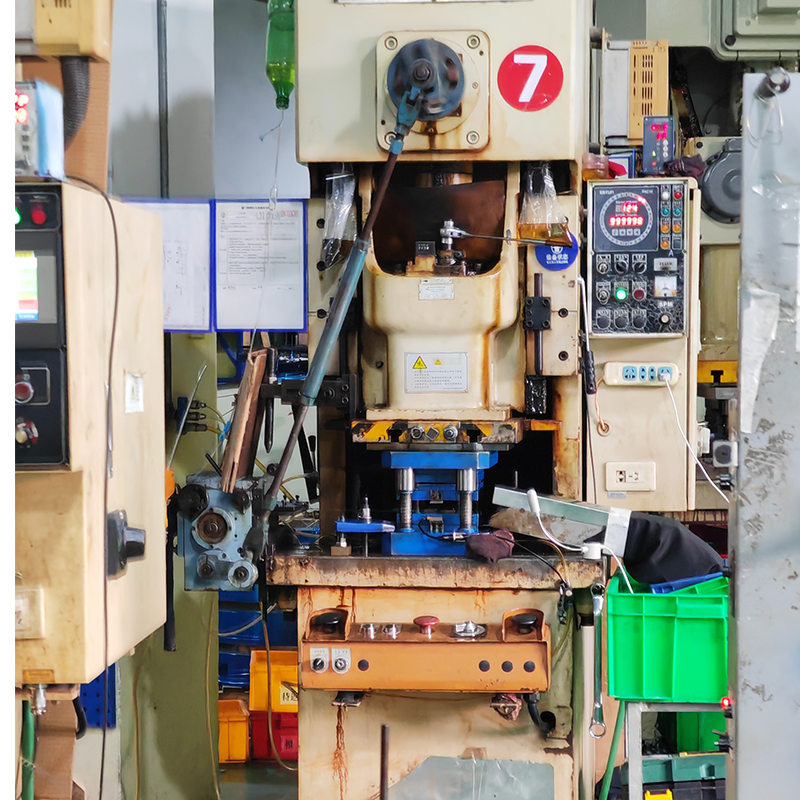

Our Factory:

We maintain an extensive array of advanced facilities and equipment to guarantee top-tier production quality. Our manufacturing capabilities include 25 punch presses with capacities ranging from 25 to 300 tons, precision wire EDM machines, grinding tools, welding and polishing equipment, as well as ultrasonic cleaning systems for impeccable finishing.

To further enhance the performance and aesthetics of our metal stamping products, we provide a comprehensive selection of metal plating solutions. These include electroplating, zinc plating, nickel plating, chrome plating, and anodizing, all conducted in cutting-edge facilities designed to deliver superior finishes, exceptional corrosion resistance, and adherence to stringent industry standards.

By integrating automated production lines, state-of-the-art machinery, meticulous quality control protocols, and premium plating techniques, we ensure our metal stamping products meet the highest levels of precision, durability, and reliability.

Reviews

There are no reviews yet.