Overview:

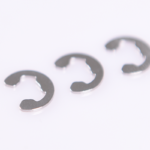

Precision tin plating metal fasteners are high-precision fasteners coated with a thin layer of tin through an electroplating process. The tin plating enhances the fasteners’ corrosion resistance, improves solderability, and provides a smooth, durable finish. These fasteners are typically made from materials such as steel, brass, or stainless steel, depending on the specific application requirements.

These precision tin-plated metal fasteners are commonly used in industries like electronics, automotive, aerospace, and telecommunications, where reliability and long-term performance are crucial. The tin coating ensures that the fasteners perform optimally in environments that require resistance to oxidation and corrosion.

At our factory, we offer customized production services for tin-plated metal fasteners, with flexible options for size, material, and surface finishes to meet the specific needs of our clients. Whether you need small or large quantities, we can tailor our fasteners to suit various industry applications, ensuring quality, precision, and timely delivery.

Details:

| Item | Details |

| Material | Copper, Iron, Stainless Steel, Brass, Aluminum, etc. |

| Mould | Multistep Progressive Dies |

| Surface Processing | Tin Plating |

| Tolerances | 0.03mm or Above |

| Customized | Yes |

| Raw Material | Iron, Stainless Steel, Brass, Aluminum, Copper, etc. |

| Usage | Home Appliances Parts, Automotive Spare Parts, etc. |

| Certificate | ISO 9001:2015, RoHS |

| Delivery Method | By Sea, By Air, or By Express Service |

| MOQ | Based on Customer Requirement |

| Accuracy | 0.03mm or Above |

| Service | OEM Service |

| Size | Customer’s Request |

| Transport Package | Custom |

| Specification | As per Customer’s Technical Drawing |

| Trademark | OEM |

| Origin | Xiamen, China |

| Production Capacity | 100,000 Pieces/Per Day |

Production Process:

- Material Selection: High-quality raw materials like copper, stainless steel, and brass are chosen for their strength and suitability for stamping and plating.

- Stamping: The material is stamped into the desired shape using progressive dies, ensuring precise dimensions and tolerances of 0.03mm or above.

- Cleaning: The stamped parts are thoroughly cleaned to remove contaminants and prepare for plating.

- Tin Plating: A thin layer of tin is electroplated onto the parts, enhancing corrosion resistance and solderability.

- Quality Control: Fasteners undergo rigorous inspection to ensure they meet precise specifications and quality standards.

- Packaging and Delivery: After passing quality checks, the fasteners are packaged and shipped according to customer requirements, with options for sea, air, or express delivery.

Our Advantages:

- Extensive Product Range: We manufacture over 2,000 types of metal parts designed for replacement applications across various industries.

- Material Flexibility: We offer a wide selection of materials, including Iron, Stainless Steel, Brass, Copper, and more, allowing you to choose the best option based on your specific requirements.

- Comprehensive OEM & Design Services: We provide tailored OEM solutions and design services to meet your unique needs and specifications.

- Fast Delivery & Rigorous Quality Control: We ensure fast turnaround times and 100% product inspection before shipment, guaranteeing high-quality standards.

- Global Reach with Competitive Pricing: We export worldwide, offering competitive pricing, superior quality, and exceptional customer service.

Our Factory:

Our advanced manufacturing facilities are equipped with a wide range of precision machinery, including 25 punch presses (25 to 300 tons), wire EDM machines, grinding equipment, welding and polishing tools, and ultrasonic cleaning systems. We also offer a variety of metal plating options—such as electroplating, zinc plating, nickel plating, chrome plating, and anodizing—to enhance the durability, appearance, and functionality of our metal stamping products. These processes ensure consistent quality, corrosion resistance, and compliance with industry standards. By combining cutting-edge equipment, automated production lines, and strict quality control measures, we deliver high-quality metal stamping products that meet the most stringent specifications.

Reviews

There are no reviews yet.