Overview:

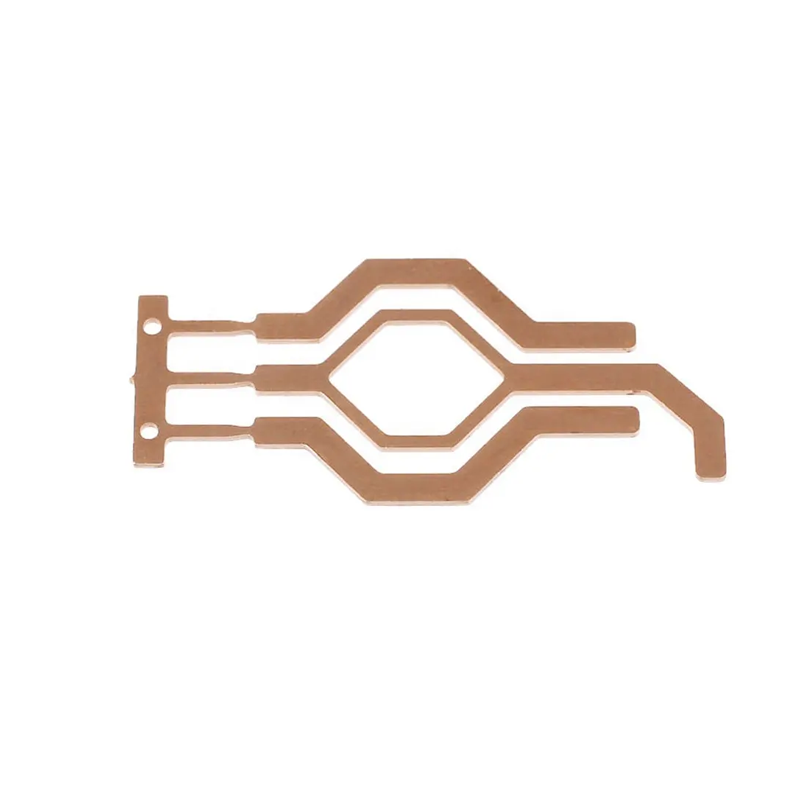

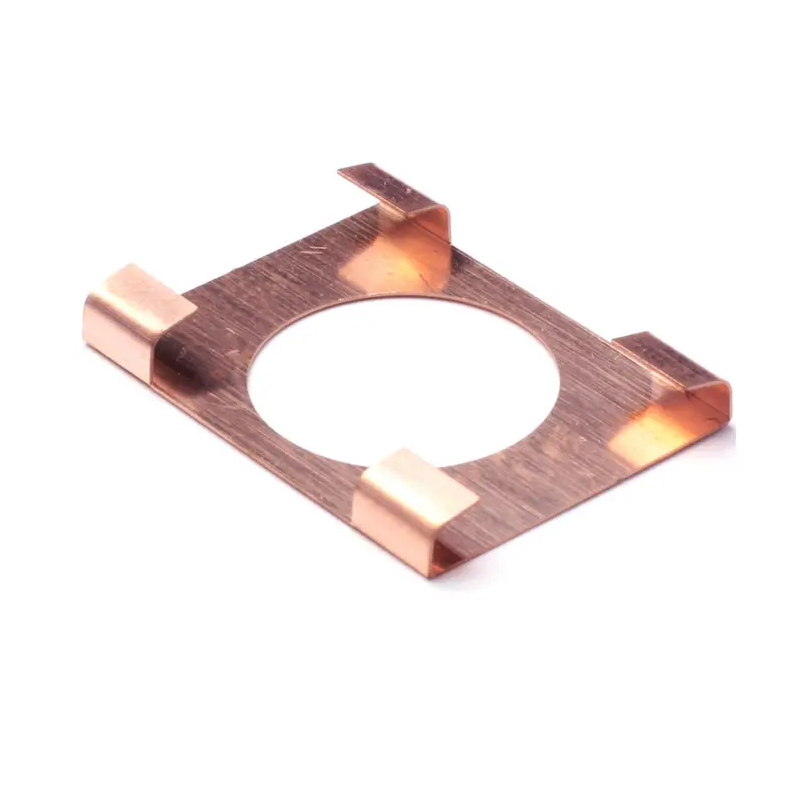

Progressive stamping electrical contacts are precision-engineered components created through the progressive stamping process, where metal sheets are progressively formed into specific shapes using a series of dies. These contacts are commonly used in automotive electronics due to their ability to provide reliable electrical connections in high-performance environments. They play a crucial role in ensuring the efficient transmission of electrical signals and power within automotive systems such as lighting, sensors, and control units.

At our factory, we specialize in the custom production of progressive stamping electrical contacts tailored to the unique needs of automotive electronics. With our advanced stamping technology and expertise in designing components for optimal performance, we deliver high-quality, durable electrical contacts that meet the strictest industry standards. Whether you need specific sizes, materials, or surface finishes, we offer fully customized solutions to ensure your automotive electronics operate flawlessly.

Details:

- Place of Origin: Xiamen, China

- Brand Name: OEM

- Process: Progressive Stamping

- Material: Copper, Brass

- Finish: Nickel Plated

- Thickness: Custom

- Tolerance: +/- 0.02

- Color: Custom

- Test: Tensile Test

- Property: Good Connecting

Production Process:

- Design and Engineering: Custom designs are created using CAD and simulations to meet technical specifications.

- Material Selection: Copper and brass are chosen for their excellent conductivity and durability.

- Progressive Stamping: The material is fed through a series of stations in a progressive die to shape, cut, and form the contacts with high precision.

- Plating and Surface Finishing: The contacts are nickel-plated or finished to improve corrosion resistance and conductivity.

- Quality Control and Testing: Rigorous testing, including tensile tests and dimensional checks, ensures compliance with standards.

- Final Assembly and Packaging: Contacts are assembled, packaged, and ready for shipment.

Other Surface Treatment Options:

- Gold Plating: Provides excellent corrosion resistance, enhanced electrical conductivity, and a superior aesthetic finish.

- Silver Plating: Offers high conductivity, improved corrosion resistance, and is ideal for electrical components requiring low contact resistance.

- Nickel Plating: Enhances durability, corrosion resistance, and wear resistance, commonly used for high-stress applications.

- Tin Plating: Provides a protective layer that resists oxidation, ideal for soldering applications and offering good corrosion resistance.

Our Factory:

We operate state-of-the-art facilities equipped with 25 punch presses (25 to 300 tons), precision wire EDM machines, grinding, welding, polishing tools, and ultrasonic cleaning systems to ensure top-quality production. Our capabilities are further enhanced with a range of metal plating processes, including electroplating, zinc plating, nickel plating, chrome plating, and anodizing, which improve durability, appearance, and functionality. With advanced equipment, automated production lines, and stringent quality controls, we consistently deliver high-quality metal stamping products that meet industry standards.

We operate state-of-the-art facilities equipped with 25 punch presses (25 to 300 tons), precision wire EDM machines, grinding, welding, polishing tools, and ultrasonic cleaning systems to ensure top-quality production. Our capabilities are further enhanced with a range of metal plating processes, including electroplating, zinc plating, nickel plating, chrome plating, and anodizing, which improve durability, appearance, and functionality. With advanced equipment, automated production lines, and stringent quality controls, we consistently deliver high-quality metal stamping products that meet industry standards.

Reviews

There are no reviews yet.