Description:

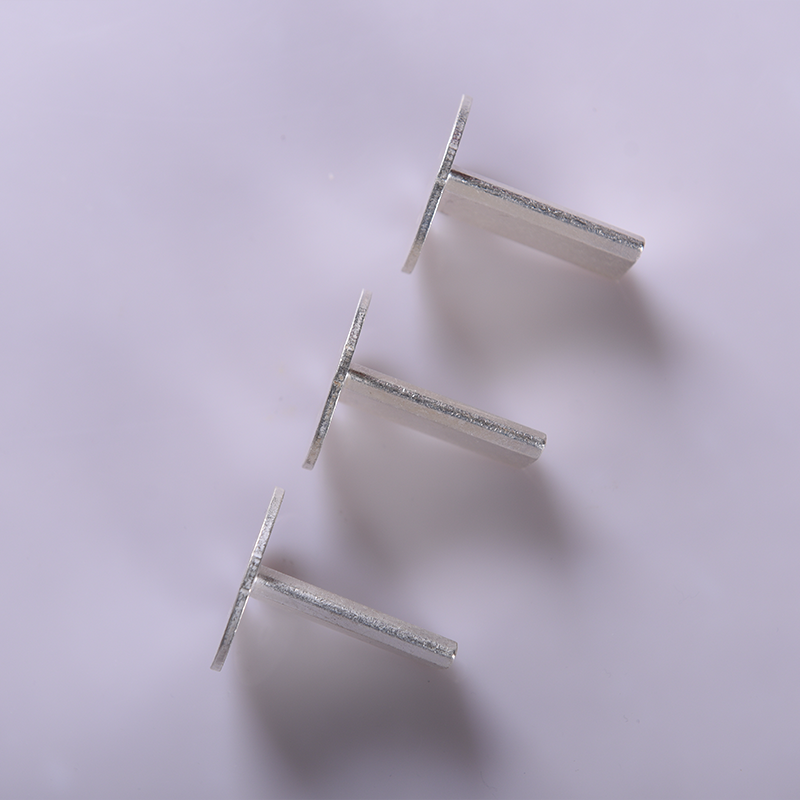

Silver plating electronic stamped contacts for electric control systems are precision components made using advanced stamping and electroplating techniques. These contacts are stamped from high-quality metals, such as copper or brass, and coated with a layer of silver to improve conductivity, corrosion resistance, and durability.

In electric control systems, these silver-plated contacts enhance electrical performance, reduce contact resistance, and ensure long-term reliability in high-frequency and high-voltage environments. They also offer superior resistance to oxidation and wear.

Our factory provides OEM customization services, including a variety of sizes, materials, and surface treatments, tailored to meet the specific needs of your electric control system. With advanced equipment and expertise, we deliver high-quality, precision-engineered products.

Characteristics:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Size | Custom |

| Sample | Available |

| Material | Copper-1100, Copper-5191, Brass-6265, Brass-7275 |

| Shipment Ways | Express Freight / Air / Sea |

| Certificate | ISO9001:2008, ROHS |

| Thickness | 0.1-0.5mm |

| Minimum Quantity | According to your requirement |

| Usage | Electric Control System |

Operation Process:

- Material Selection: High-quality metals such as copper-1100, copper-5191, brass-6265, or brass-7275 are chosen for their excellent electrical conductivity and durability.

- Stamping: The selected material is precisely stamped using advanced tooling and progressive dies to form the desired contact shape. The stamping process ensures tight tolerances and uniformity in dimensions.

- Surface Preparation: The stamped contacts undergo thorough cleaning to remove any impurities, oils, or contaminants, ensuring a clean surface for the electroplating process.

- Silver Plating: A thin layer of silver is electroplated onto the contacts to enhance electrical conductivity, corrosion resistance, and overall durability. The plating process ensures consistent coating thickness and high-quality finish.

- Inspection & Testing: After plating, the contacts undergo rigorous quality checks, including electrical conductivity testing, dimensional inspection, and visual checks for defects. This ensures that all parts meet the required standards for electric control system applications.

- Packaging & Shipping: Once the contacts pass all quality control measures, they are packaged and shipped according to customer specifications, with options for express, air, or sea delivery.

Other Surface Treatment Options:

– Gold Plating: Enhances conductivity, corrosion resistance, and appearance, ideal for high-performance electronics.

– Nickel Plating: Provides durability and protection against wear and corrosion, improving part longevity.

– Tin Plating: Offers corrosion resistance and improved solderability, commonly used for cost-effective protection.

These treatments optimize the performance and lifespan of metal components across various industries.

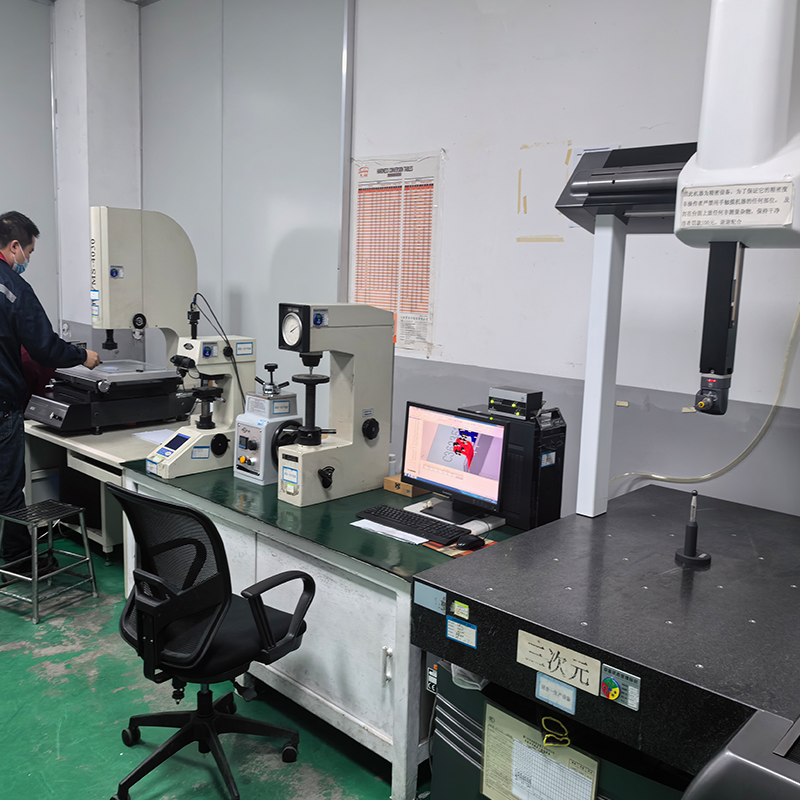

Quality Control Process:

Our quality control process for silver-plated electronic stamped contacts for electric control systems is built on rigorous standards to consistently exceed customer expectations. We follow well-defined procedures and maintain a fully equipped inspection department to ensure each component meets stringent specifications. All incoming raw materials are thoroughly documented for traceability, and our inspection tools are regularly calibrated for accuracy. We offer optional analysis reports to further verify compliance, and non-conforming parts are isolated for careful review. Root cause analysis is conducted for any quality deviations, with corrective actions implemented to prevent recurrence. Additionally, we foster a culture of continuous improvement by encouraging staff to propose enhancements in methods, materials, and suppliers. This thorough approach guarantees the highest quality and reliability for our silver-plated components, ensuring they perform optimally in electric control systems.

Reviews

There are no reviews yet.