Overview:

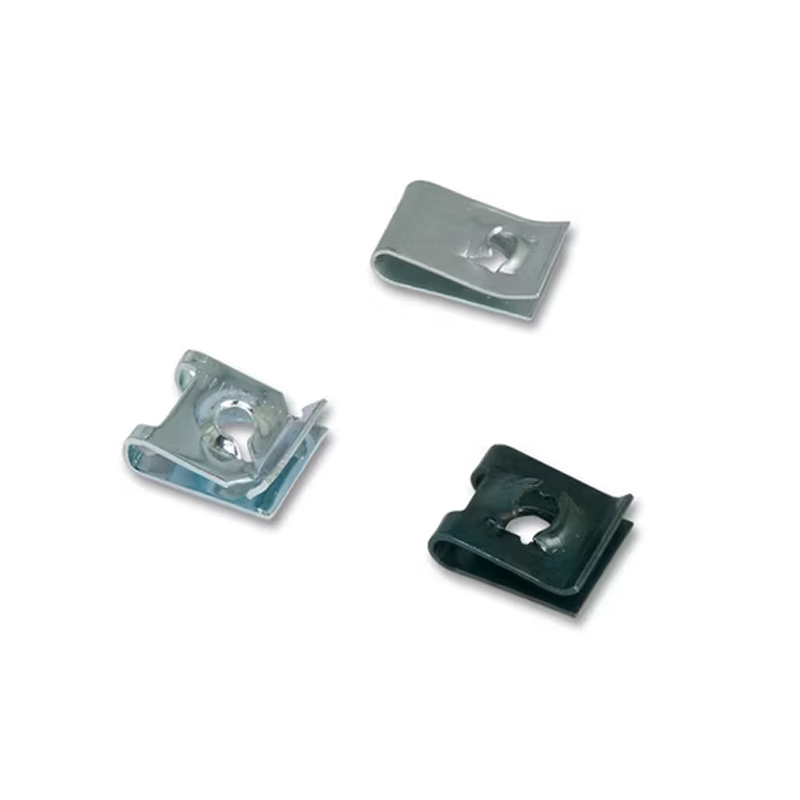

Stainless Steel Acid Passivation Metal Stamping Clips are high-precision components manufactured through metal stamping processes. These clips are made from durable stainless steel and undergo an acid passivation treatment to enhance their resistance to corrosion, improve durability, and maintain consistent performance in harsh environments. The acid passivation process provides a protective layer that increases the longevity of the clips, making them ideal for applications that require high strength and resistance to wear and corrosion.

These clips are commonly used in automotive, electrical, aerospace, and industrial applications where reliability and longevity are essential. Their superior durability makes them suitable for use in a variety of critical systems and environments.

We offer OEM customization services, including options for size, dimensions, and various surface treatments such as zinc plating, nickel plating, or powder coating to meet specific application requirements. Contact us for precision-engineered metal stamping clips tailored to your needs.

Details:

| Attribute | Details |

| Material | Stainless Steel |

| Mould | Multistep Progressive Dies |

| Surface Processing | Stainless Steel – Acid Passivation |

| Process | Forming Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.01mm |

| Customization | Warmly Welcomed |

| Delivery Date | 15 Days |

| Place of Origin | Xiamen, China |

| Transport Package | Custom |

| Specification | Customized |

| Trademark | OEM |

| Size | Custom |

Other Surface Treatments Options:

Gold Plating: A high-quality plating process where a thin layer of gold is deposited onto the metal surface. This treatment provides excellent corrosion resistance, enhances electrical conductivity, and improves aesthetic appeal, making it ideal for high-end electronic applications.

Silver Plating: A surface coating of silver applied to the metal to improve electrical conductivity and corrosion resistance. Silver plating is commonly used in electronic, automotive, and industrial applications for superior performance and longevity.

Nickel Plating: A versatile surface treatment that provides excellent protection against corrosion and wear. Nickel plating enhances the durability and appearance of metal stamping clips, making them ideal for use in environments exposed to moisture and chemicals.

Tin Plating: A corrosion-resistant coating applied to metal parts to improve solderability, electrical conductivity, and protection against corrosion. Tin plating is commonly used in the manufacturing of metal stamping clips for the electronics industry, ensuring reliable performance in various applications.

Production Process:

- Material Selection: High-quality stainless steel is selected based on the desired strength, durability, and corrosion resistance required for the final product.

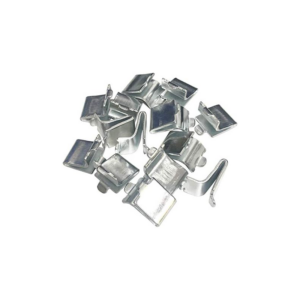

- Metal Stamping: The stainless steel sheet is fed into precision progressive stamping dies that cut, form, and shape the clips into their desired design. This process ensures high precision and consistency for each part.

- Forming Process: The stamped clips undergo further forming operations to achieve the correct geometry and dimensions, ensuring proper fit and functionality in their final applications.

- Acid Passivation Treatment: After forming, the clips undergo an acid passivation process, where they are treated with a special acid solution to remove free iron from the surface. This creates a passive oxide layer that enhances the clips’ corrosion resistance and protects against rust and oxidation.

- Inspection and Quality Control: Each metal stamping clip is carefully inspected for dimensional accuracy, surface quality, and functional integrity. This step ensures that the clips meet the highest standards for durability and performance.

- Packaging and Delivery: The finished stainless steel clips are carefully packaged to prevent damage during transport. Custom packaging options are available based on customer requirements, ensuring safe and secure delivery.

Factory Overview:

We operate a diverse range of advanced manufacturing facilities designed to ensure optimal production quality. Our plant is equipped with 25 high-performance punch presses, ranging from 25 tons to 300 tons, along with precision wire EDM machines, grinding and polishing equipment, welding tools, and ultrasonic cleaning systems, all of which contribute to the efficient and precise production of metal components.

In addition to our core manufacturing capabilities, we offer an extensive selection of metal plating services to enhance the functionality, durability, and aesthetic appeal of our stamped products. These processes include electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our cutting-edge plating facilities are designed to deliver consistent, high-quality finishes that provide superior corrosion resistance and adhere to rigorous industry standards.

By integrating automated production lines, state-of-the-art mechanical equipment, comprehensive quality control measures, and advanced plating techniques, we ensure that every metal stamping product we produce meets the highest standards of precision, performance, and reliability.

Reviews

There are no reviews yet.