Overview:

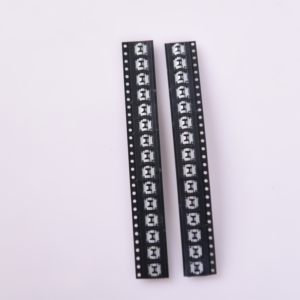

Stamped Metal Spring Clip Parts are precision-engineered components typically used for securing or fastening applications in various industries, including automotive, electronics, and aerospace. These parts are made through the metal stamping process, which involves using a high-pressure press to shape metal sheets into specific designs. The stamping process can be performed using various materials such as stainless steel, carbon steel, brass, aluminum, and other alloys.

At our factory, we design, manufacture, and assemble custom clips in a wide variety of shapes and sizes. We also offer secondary services such as vacuum hardening, oil quenching, and Austempering, ensuring that our clips meet rigorous performance standards. In addition, we provide unlimited plating resources such as zinc, nickel, and chrome plating, which enhance corrosion resistance and improve the overall functionality of the parts. Learn more about the shape, size, and material options available when you partner with us for your custom metal clips, and let us deliver the best solutions for your needs.

Features:

| Category | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Aluminum, Steel, Stainless Steel, Brass, Copper, Iron, etc. |

| Surface Treatment | Painting, Powder Coating, Plating, Polishing |

| Process | Metal Stamping |

| Tolerance | 0.01mm |

| Certification | ISO9001:2005 |

| Drawing Format | 2D/3D/CAD/DWG/STEP/PDF/IGS |

| MOQ | Small Orders Can Be Accepted |

| OEM | Accepted |

| Package | According to Customer Requirements |

Quality Control Process:

At Topmetalstamping, quality is at the heart of our metal spring clip production. We start with a thorough feasibility review to ensure manufacturability and conduct a run-at-rate study during the first run to confirm quality before full-scale production. Our quality management system combines advanced technology, continuous improvement, and a skilled team to guarantee 100% defect-free products.

Using customized in-line and off-line camera vision systems, we inspect every part’s features and dimensions, ensuring precision and quality throughout the production process. Trust Topmetalstamping for reliable, high-performance metal spring clips delivered on time, every time.

Why Choose Us?

Customized OEM Solutions & Full Assembly Services

With over 20 years of expertise, we specialize in delivering tailored OEM solutions and comprehensive assembly services. Our advanced manufacturing capabilities ensure that we meet your specific requirements, providing top-tier quality and performance with every product.

Wide Range of Products

We offer a diverse portfolio of products, including precision-stamped components, CNC-machined parts, springs, shafts, fasteners, and more. As your trusted, full-service partner, we optimize processes to efficiently handle all aspects of your project, from initial design to final production.

Industry Certifications & Expertise

As an established second-tier supplier, we have successfully passed rigorous factory audits and hold key industry certifications, such as RoHS and HE compliance. This guarantees that our products adhere to the highest global quality standards and regulatory guidelines.

Commitment to Quality Excellence

Our ISO 9001:2015 and IATF 16949 certifications demonstrate our unwavering commitment to quality management. These certifications ensure that every part we produce is crafted with precision and durability, maintaining the highest standards across all production phases.

Our Factory:

We operate a fully equipped manufacturing facility with a wide range of advanced machinery, including 25 punch presses (25 to 300 tons), precision wire EDM machines, grinding equipment, and ultrasonic cleaning systems. To enhance the durability, appearance, and functionality of our metal stamping products, we offer a variety of plating options, such as electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our state-of-the-art plating facilities ensure consistent finishes, corrosion resistance, and compliance with industry standards. This combination of automated production lines, high-quality equipment, and stringent quality control guarantees that we consistently deliver top-tier metal stamping products.

Reviews

There are no reviews yet.