Overview:

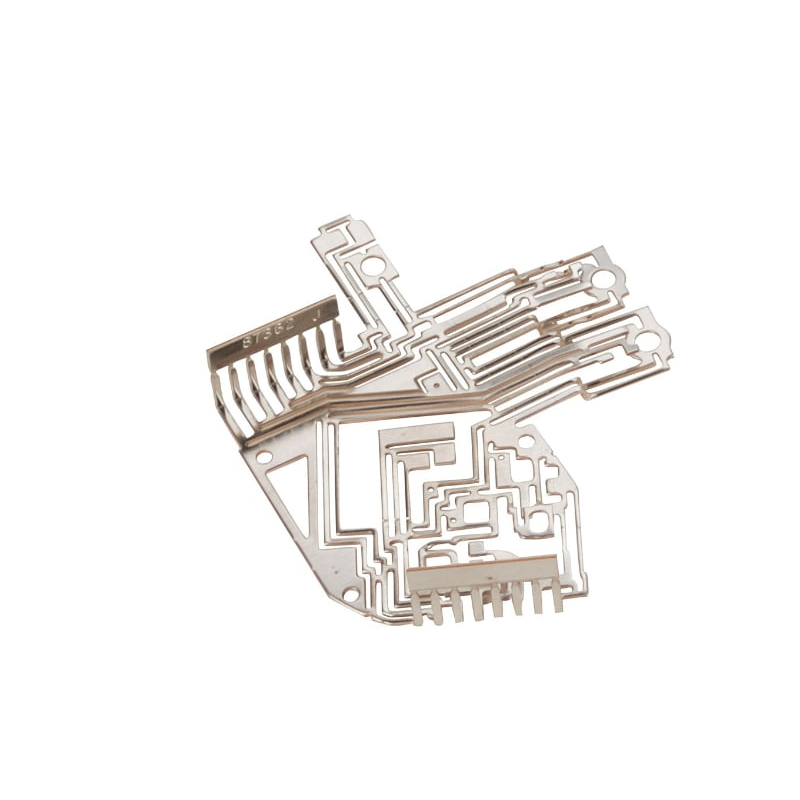

At Topmetalstamping, we specialize in the design and manufacturing of high-precision lead frames, featuring advanced tin plating for superior corrosion resistance and enhanced solderability. Our lead frames are meticulously crafted to ensure secure and reliable electrical connections, crucial for the optimal performance of microprocessors and other semiconductor devices. Engineered with precision, our products meet the rigorous demands of automotive, electronic, and microprocessor applications, delivering unmatched functionality and durability. Trust Plantmetal for your lead frame needs, where cutting-edge manufacturing processes ensure the highest standards of quality and performance.

Basic Information:

- Place of Origin: Xiamen, China

- Brand Name: OEM

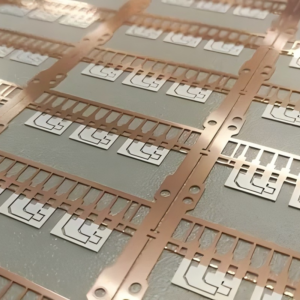

- Material: Copper

- Product Name: Lead Frame

- Application: Medical, Industrial, Electronics

- Service: Customized OEM

- Surface Treatment: Available upon request

- Size: Customized size options

- Logo: Etched with your company logo

- Surface Finish: No burrs or marks; very clean

- Thickness: 0.05 mm – 0.1 mm

- Color: Customized color options available

Surface Treatment Options:

- Chemical Passivation: This process creates a protective, inert surface layer, significantly improving corrosion resistance and prolonging the component’s service life.

- Gold Electroplating: A precision coating that enhances conductivity, corrosion resistance, and wear protection, making it ideal for demanding high-performance applications.

- Silver Electroplating: Known for its excellent electrical conductivity and resistance to oxidation, this coating is commonly used in electrical and electronic components to ensure reliable performance.

- Nickel Electroplating: A highly durable coating that provides increased strength, wear resistance, and corrosion protection, serving as a solid foundation for additional plating layers.

Production Process:

- Material Preparation: Premium copper or copper alloys are thoroughly cleaned to remove impurities and ensure a flawless surface for stamping and plating processes.

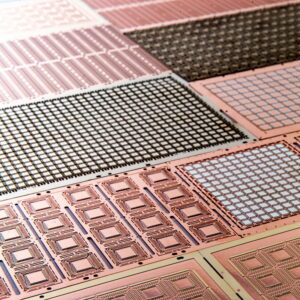

- Precision Stamping: The material is precision-stamped using advanced machinery to create intricate designs with tight tolerances, ensuring consistency and accuracy in every component.

- Deburring and Cleaning: After stamping, sharp edges and residues are carefully removed to achieve a smooth, defect-free surface, preparing the component for further processing.

- Tin Plating: A thin, uniform layer of tin is electroplated onto the lead frame, providing enhanced corrosion resistance, improved solderability, and ensuring stable and reliable electrical connections.

- Post-Treatment: Following plating, the components are rinsed, dried, and treated with anti-tarnish coatings to preserve the plated surface, ensuring long-lasting durability and optimal performance.

- Quality Control: Each batch undergoes stringent inspection for dimensional precision, surface finish, and overall functionality, ensuring compliance with industry standards and customer specifications.

- Packaging: The lead frames are carefully packaged using protective materials to safeguard them during transit, ensuring they arrive in perfect condition for assembly and use.

Our Manufacturing Capabilities:

Our state-of-the-art production facility is equipped with 25 punch presses ranging from 25 to 300 tons, along with advanced wire EDM, grinding, welding, and polishing machinery. We also offer a range of sophisticated ultrasonic cleaning systems to ensure precision and cleanliness in every part.

To further enhance the performance, longevity, and visual appeal of our components, we provide a variety of high-quality metal plating options, including electroplating, zinc, nickel, chrome plating, and anodizing.

With a strong emphasis on automation, advanced machinery, and stringent quality control measures, our facility consistently produces metal stamping solutions that meet the highest industry standards for reliability and excellence.

Reviews

There are no reviews yet.