Overview:

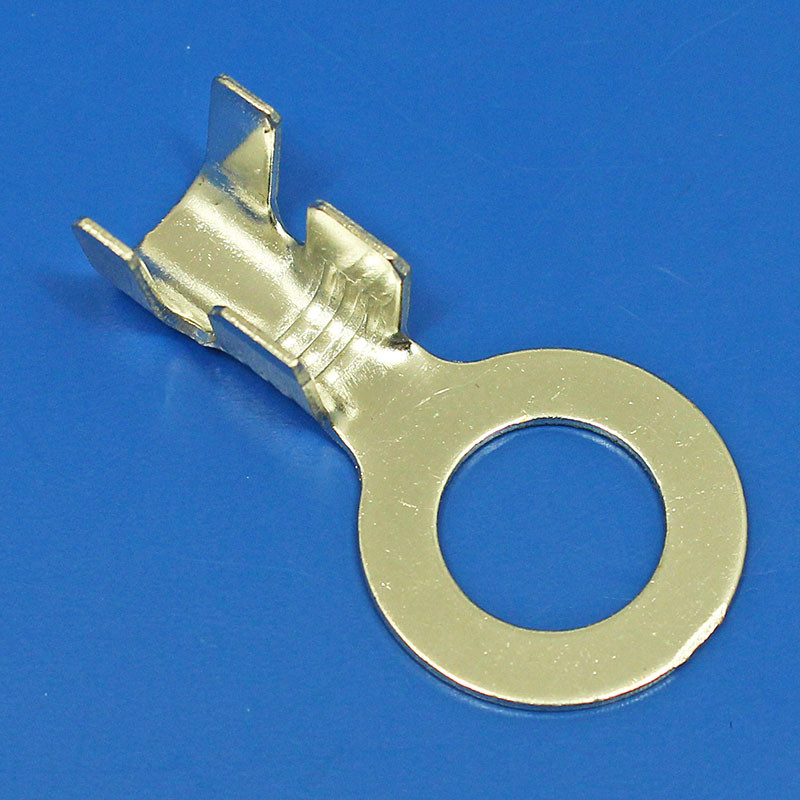

Tinned brass ring metal terminals are electrical connectors made from high-quality brass that is coated with a layer of tin for improved corrosion resistance and conductivity. These terminals are widely used in various electrical and electronic applications, providing reliable connections in a range of devices. The manufacturing process typically involves stamping or precision machining to create the desired shape, followed by a tin plating process to enhance durability and performance. At Thesun Industry, we offer OEM services and can customize tinned brass ring terminals in various sizes and configurations to meet the specific needs of our clients, ensuring versatility for different applications.

Features:

| Attribute | Details |

| Material | Copper |

| Application | Conduct Electricity, Transmission of Electrical Signals |

| Character | High Temperature Resistance |

| Species | Terminal |

| Production Process | Cold Pressing |

| Shape | Custom |

| Certification | OEM |

| Trademark | OEM |

| Size | Custom |

| Origin | Xiamen, China |

| Surface Treatment | Tin Plating, Nickel Plating, Gold Plating, Silver Plating, Electroplating, Oxidation |

Production Process:

- Material Preparation: High-quality copper or brass is selected as the base material for the terminals. The metal is often in the form of strips or wires that are ready for shaping.

- Cold Pressing: The metal is shaped into the terminal form using a cold pressing technique. This process uses a punch and die to cut and mold the metal into the desired ring terminal shape.

- Tin Plating: After the terminal shape is formed, the metal undergoes a tin plating process. This involves coating the brass or copper terminals with a thin layer of tin to enhance their resistance to corrosion and improve electrical conductivity.

- Quality Control: The finished terminals are inspected for defects and tested for performance. This ensures they meet industry standards for electrical conductivity, durability, and functionality.

- Customization (if needed): Based on customer requirements, terminals can be further customized in terms of size, shape, and specifications.

- Packaging: Finally, the completed tinned brass ring metal terminals are carefully packaged for shipping, ensuring that they are protected from damage during transportation.

Quality Assurance:

The quality control process for tinned brass ring metal terminals involves several essential steps to ensure they meet the highest standards of performance and reliability. First, visual inspection is performed to check for any visible defects, such as cracks, improper plating, or dimensional inaccuracies. Next, dimensional measurement is conducted using precision equipment like CNC coordinate measuring machines (CMM) to ensure the terminals meet exact specifications. Then, electrical conductivity testing is carried out using specialized instruments to verify the effectiveness of the tin plating in ensuring a reliable electrical connection. The terminals are also subjected to corrosion resistance testing, often through salt spray chambers, to simulate long-term environmental exposure. Finally, mechanical strength testing, using machines like tensile testers, ensures that the terminals can withstand the required load and pressure. Throughout this process, advanced testing equipment and machines guarantee that every batch of tinned brass ring metal terminals is of the highest quality, meeting both industry standards and customer requirements.

Factory Show:

Reviews

There are no reviews yet.