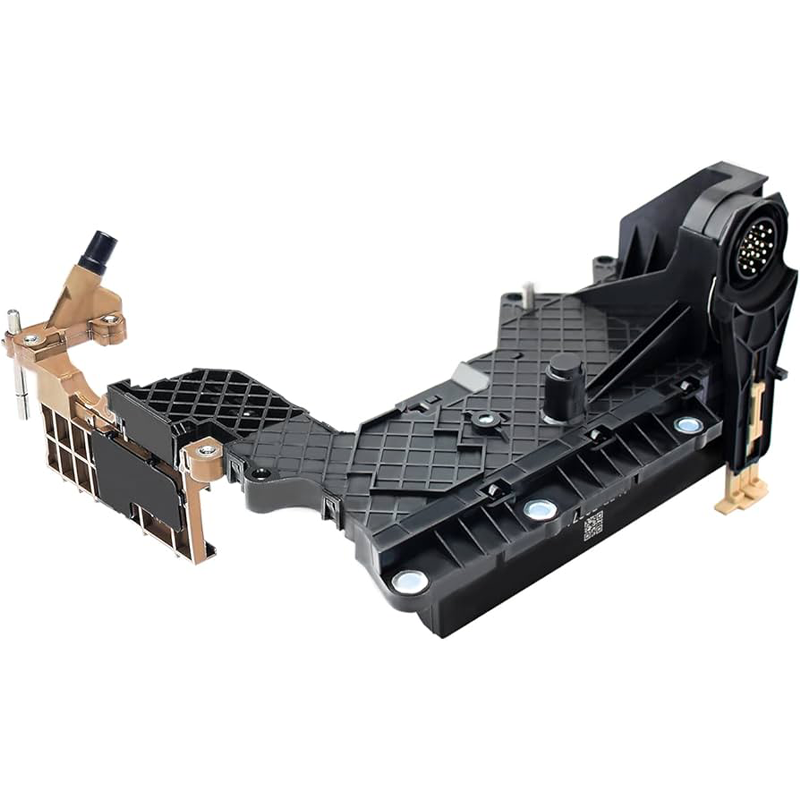

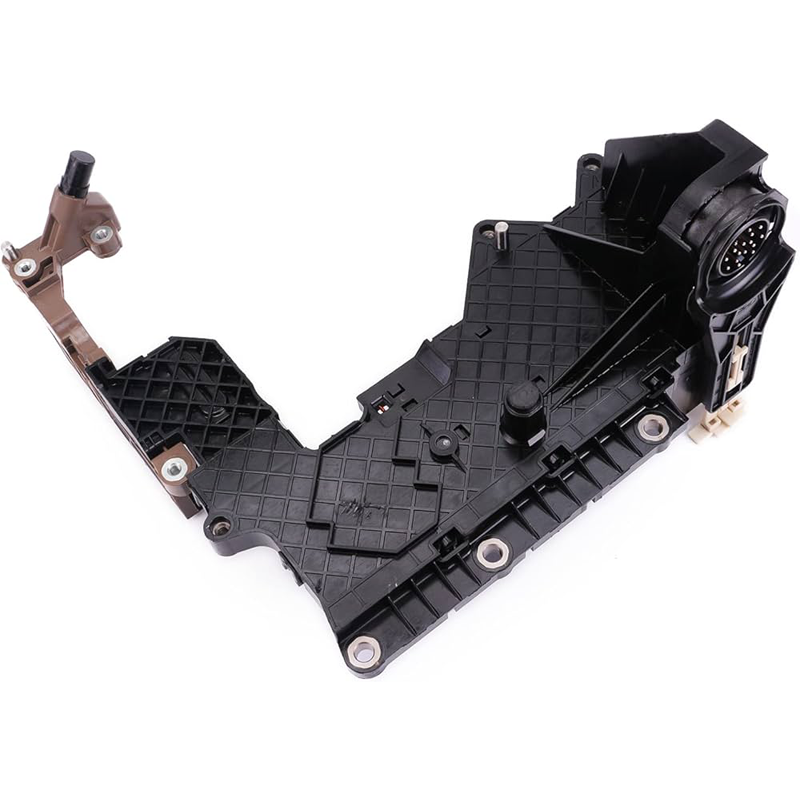

A transmission lead frame is a critical component in automatic transmissions, responsible for connecting various electrical sensors and solenoids to the vehicle’s electronic control unit (ECU). Made from durable metal or plastic materials, it ensures efficient communication and transmission of signals between the transmission system and the ECU. This precise coordination helps regulate gear shifts, monitor transmission performance, and ensure smooth operation. Commonly used in vehicles like the Ford F-150, transmission lead frames are essential for maintaining optimal driving performance, and issues with them may lead to recalls or replacements for improved functionality.

Basic Information

Place of Origin :Xiamen, China

Brand Name :OEM

Material: High-quality plastics/ Metal

Type :Hardware Parts

Size :Customized Size

Surface treatment :Galvenized/ Custom

Certificate: ISO9001:2015/IATF16949

Delivery: by sea/air/express

Service Customized: OEM

Application: Industrial

Advantages of Our Product

Lighter weight

Lower cost

Higher load-carrying capacities

More resistant to shock loads and oscillations

More tolerant of shaft misalignments

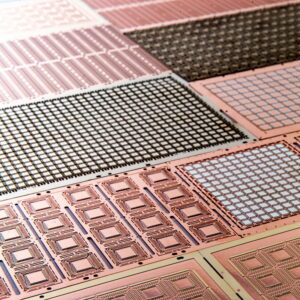

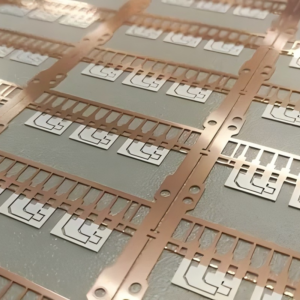

The Production Process for Our Metal Stamping Parts:

- Order Receipt and Drawing Review

– Receive and review customer orders, including technical drawings in formats such as DXF, IGS, STEP, or PDF.

- Design Confirmation

– Confirm design details with the customer to ensure accuracy before production begins.

- Material Preparation

– Select and prepare metal sheets according to the required specifications.

- Precision Cutting

– Utilize laser cutting and CNC shearing to cut metal sheets to precise dimensions.

- Forming and Shaping

– Perform bending, punching, and stamping to achieve the desired shapes and features.

- Welding and Riveting

– Join metal components using advanced welding techniques and riveting.

- Surface Treatment

– Apply necessary surface treatments, including plating and spraying, to enhance durability and appearance.

- Assembly and Quality Control

– Assemble the components and conduct rigorous quality checks to ensure adherence to specifications.

- Packaging and Shipping

– Package finished parts securely and manage logistics for timely delivery to the customer.

- After-Sales Support

– Provide ongoing support and address any post-delivery issues to ensure customer satisfaction.

Reviews

There are no reviews yet.