When it comes to precision manufacturing, one process stands out as both intricate and indispensable: wire forming. While it may seem like a highly specialized technique, wire forming is at the heart of many industries, including automotive, medical devices, aerospace, and electronics. Whether you’re designing a critical component for a smart home device or crafting robust automotive parts, understanding the process of wire forming can provide a competitive edge. In this blog post, we’ll explore everything you need to know about wire forming, from methods to applications, and highlight how it can benefit your manufacturing projects.

What is Wire Forming?

Wire forming is the process of shaping, bending, cutting, and assembling metal wires into precise shapes and structures to meet specific application requirements. This technique allows manufacturers to create both simple and complex components used across multiple industries, from springs and clips to custom fasteners and brackets. Wire forming combines both artistry and engineering, as the metal wire is manipulated with the help of tools, machines, and technology to create parts that meet both functional and aesthetic demands.

In essence, wire forming takes a raw material—typically stainless steel, brass, or copper—and transforms it into a part that serves a functional purpose, such as a spring, hook, or fastener. This process is critical for products found in everything from medical devices and consumer electronics to aerospace components and automotive parts.

Key Stages of the Wire Forming Process

Wire forming is not just a single-step process—it involves several critical phases that ensure high-quality, precision products. Let’s take a closer look at each of these stages:

1. Material Selection

The wire forming process begins with choosing the appropriate metal for the task at hand. Depending on the application, materials such as stainless steel, aluminum, brass, or copper are selected. Each material has its own set of properties, such as tensile strength, flexibility, and corrosion resistance, making them ideal for various uses in different industries.

2. Wire Straightening

After the raw wire is selected, the next step is straightening. Raw wire often comes in coils that may be bent or curved. To ensure precision in later stages of the process, the wire is straightened, typically using machines designed specifically for this task. This ensures uniformity in the final product.

3. Cutting

Once the wire is straightened, it’s cut into precise lengths. Accurate cutting ensures that the final product will meet the required specifications and dimensions. Precision in this step is crucial for the next stages, where the wire will be shaped into its final form.

4. Bending and Shaping

The core of the wire forming process lies in the bending and shaping stages. Using advanced machines, including CNC wire forming equipment, operators shape the wire into the desired configurations. This step is where the wire takes on its intended form—whether it’s a coil spring, hook, or clip. The use of CNC machines allows for high levels of accuracy and repeatability, ensuring that every part is uniform.

5. Heat Treatment

In some cases, wire forms may require heat treatment to improve their mechanical properties. This process involves heating the wire to a specific temperature and then cooling it rapidly to achieve the desired hardness, strength, or flexibility. Heat treatment enhances the durability and performance of wire forms in demanding applications, such as automotive and aerospace components.

6. Finishing

Finally, the wire forms undergo finishing treatments, which may include coating, plating, or polishing. These treatments serve multiple purposes, such as providing a protective layer to prevent corrosion, improving electrical conductivity, or simply enhancing the appearance of the final product.

Types of Wire Forming Methods

Wire forming can be achieved through a variety of methods, each tailored to specific production needs. Let’s explore some of the most commonly used techniques:

Manual Wire Forming

This method involves using hand tools and simple machines to shape wire, making it ideal for low-volume, custom designs. Manual wire forming is highly flexible and allows for intricate detailing and one-of-a-kind designs.

Coil Wire Forming

Coil wire forming specializes in the creation of springs, using a mandrel to wind the wire into helical coils. This method is perfect for components that require elasticity, such as compression springs and torsion springs.

Roll Wire Forming

Roll wire forming involves passing wire through a series of rollers that gradually shape it into flat or specific profiles. This method is commonly used for high-volume production of components like clips, pins, and other elongated parts.

Bending Wire Forming

This method uses CNC machines to perform precise bending of wire. It’s ideal for high-volume manufacturing of parts that require multiple bends or complex shapes, such as automotive seat frames or medical device components.

Fourslide Wire Forming

Fourslide wire forming is a high-precision method that uses multiple tools approaching the wire from different angles. This process is well-suited for producing intricate parts that require complex bends, such as electrical connectors and complex clips.

Hydraulic and Pneumatic Wire Forming

Both hydraulic and pneumatic wire forming use pressurized systems to shape thicker and stronger wires. Hydraulic forming provides substantial force and control, while pneumatic systems offer speed and efficiency for medium to high-volume runs.

CNC Wire Bending

CNC wire bending is one of the most accurate methods, utilizing computer-controlled machines to bend wire into highly precise shapes. This process is flexible, quick to set up, and ideal for producing both small and large production runs with high repeatability.

Applications of Wire Forming

Wire forming serves a wide range of industries and is used in the creation of numerous components and parts. Some of the key applications include:

- Automotive: Seat frames, exhaust hangers, brake clips

- Medical Devices: Surgical staples, orthodontic brackets, implants

- Aerospace: Safety wire, locking mechanisms, fasteners

- Electronics: Terminals, electrical connectors, grounding clips

- Home Appliances: Dishwasher racks, refrigerator shelves, wire baskets

- Retail Displays: Hooks, product racks, display shelving

Wire forming is a versatile manufacturing process that ensures precision, durability, and efficiency. From custom wire forms for specialized products to mass-produced components, wire forming plays a pivotal role in modern manufacturing.

Why Choose Topmetalstamping for Your Wire Forming Needs?

At Topmetalstamping, we specialize in high-quality wire forming for a wide range of applications. With years of experience in precision manufacturing, we offer custom wire forming solutions that meet your exact specifications. Whether you need springs, clips, fasteners, or custom-designed wire forms, our team has the expertise and technology to deliver top-tier results.

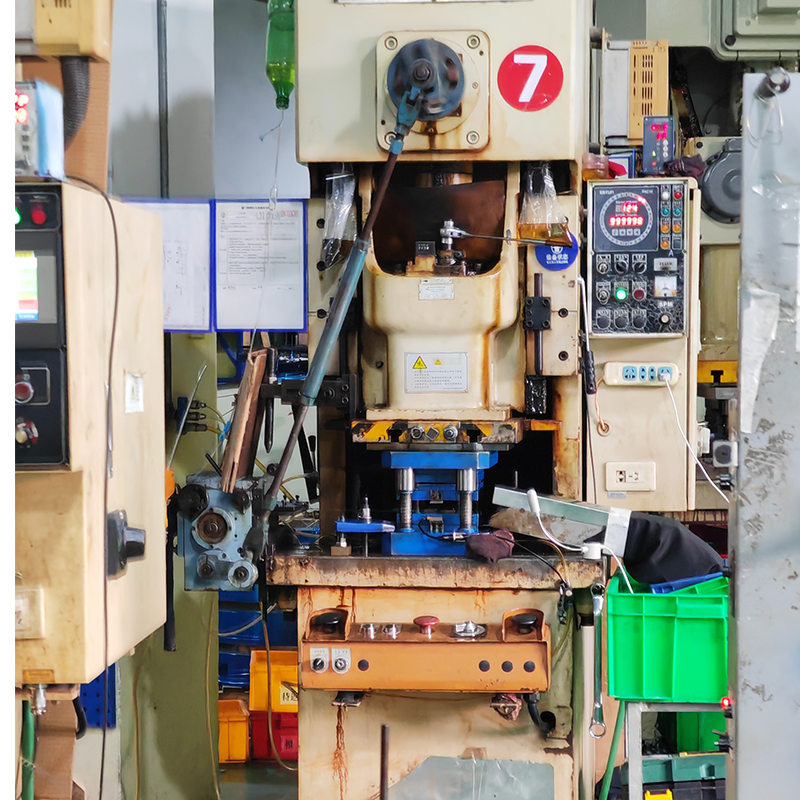

Our state-of-the-art facilities, including CNC wire bending machines, hydraulic and pneumatic presses, and advanced heat treatment and finishing capabilities, allow us to create wire forms with unparalleled precision and durability. We also offer custom services to ensure that every part we produce meets the unique requirements of your project.

We understand that quality, precision, and timely delivery are critical to your success, which is why we employ strict quality control measures and a customer-focused approach. From the initial design to final production, Topmetalstamping is your trusted partner for all your wire forming needs.

Ready to Get Started? If you’re looking for custom wire forms for your next project, don’t hesitate to reach out. Whether you need a single prototype or high-volume production, we’re here to help. Contact Topmetalstamping today, and let us provide you with the wire forming solutions that drive your success.