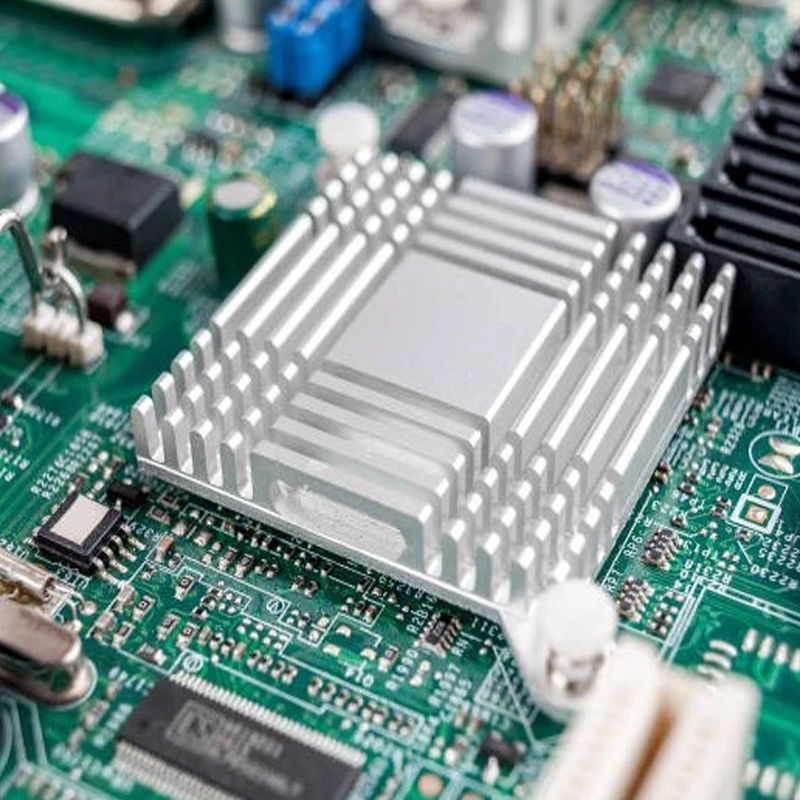

In today’s fast-paced technological landscape, electronic devices are evolving rapidly, becoming more compact, powerful, and energy-intensive. As devices become more advanced, managing heat effectively is becoming increasingly challenging. Excessive heat not only reduces the performance of electronics but can also lead to permanent damage and premature failure. This is where custom heat sinks come into play. At Topmetalstamping, we understand the importance of tailored solutions for effective heat management, which is why we specialize in providing high-quality, custom-designed heat sinks that ensure your electronic devices run efficiently and reliably.

The Growing Need for Heat Dissipation in Advanced Electronics

As devices continue to shrink in size and increase in power, the issue of heat management becomes more pronounced. Processors, power supplies, and other critical components generate significant amounts of heat that, if not managed correctly, can cause malfunctions, shorten lifespans, or even render devices unusable. Effective thermal management is no longer a luxury—it is a necessity.

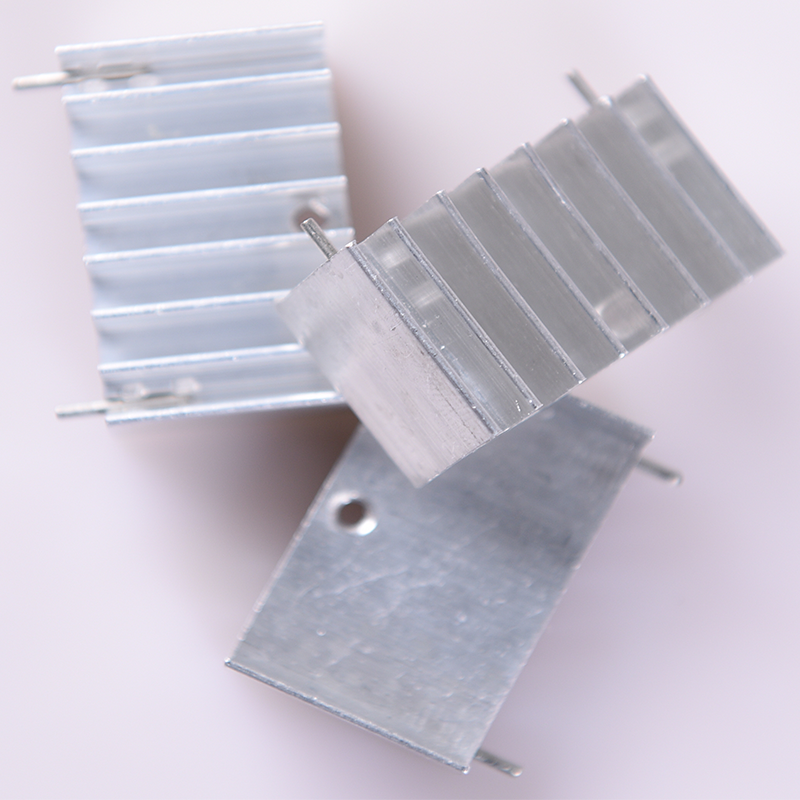

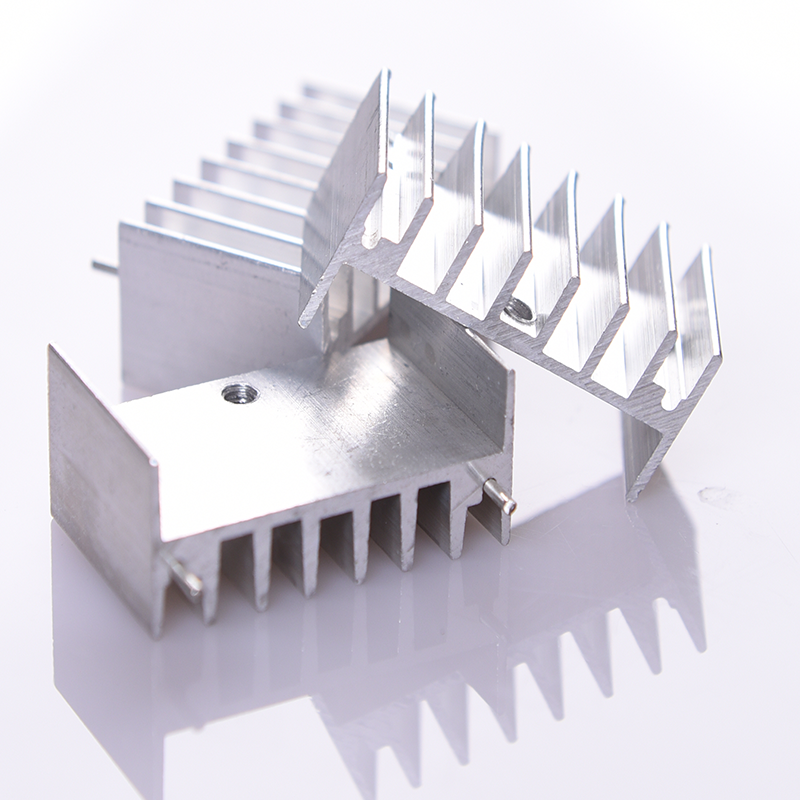

Custom heat sinks are an essential solution for tackling these challenges. Unlike generic, off-the-shelf heat sinks, custom-designed heat sinks are tailored to fit the unique dimensions, thermal requirements, and spatial constraints of each device. This level of precision ensures that heat is dissipated more effectively, which in turn improves the device’s performance, reliability, and longevity. At Topmetalstamping, we offer state-of-the-art custom heat sink solutions that are engineered to meet the specific needs of your projects.

Tailored Designs for Maximum Efficiency

The primary advantage of custom heat sinks lies in their ability to provide a perfect fit for the device they are intended for. Customization ensures that the heat sink’s design is optimized for the specific thermal load and spatial constraints of the device. Standard heat sinks, although functional, often fail to deliver the level of performance required in high-end or uniquely designed devices.

At Topmetalstamping, we specialize in crafting heat sinks that are not only precisely designed for your application but also offer enhanced thermal conductivity. Materials such as aluminum, copper, and thermal plastics are often used in the production of custom heat sinks. Each material offers distinct benefits in terms of thermal conductivity, weight, and overall efficiency.

– Aluminum: Known for its light weight and excellent thermal conductivity, aluminum is a popular choice for custom heat sinks. It strikes the perfect balance between performance and cost-effectiveness.

– Copper: With its superior thermal conductivity, copper is ideal for applications where efficient heat dissipation is critical, though it comes at a higher price point.

– Thermal Plastics: These materials offer flexibility and can be molded into intricate shapes. While not as thermally conductive as metals, they are often used in less demanding applications or where weight is a concern.

Our team at Topmetalstamping works closely with you to select the most appropriate material and design for your specific needs, ensuring that your electronic devices benefit from optimal cooling performance.

Enhanced Reliability and Longevity

One of the most significant benefits of custom heat sinks is their ability to extend the lifespan of electronic devices. High temperatures are a major factor in the premature failure of electronic components. When components are exposed to excessive heat, their lifespan is significantly shortened, and they are more likely to fail under stress. By dissipating heat efficiently, custom heat sinks keep these components cooler, reducing the likelihood of thermal degradation and enhancing the device’s reliability.

Custom heat sinks allow for more targeted cooling, ensuring that the most heat-sensitive areas of your device receive the necessary thermal management. By lowering the operating temperature, these heat sinks not only prolong the life of the device but also help maintain its performance over time. This is especially critical in industries like telecommunications, automotive, and medical devices, where device reliability is of utmost importance.

Energy Efficiency

As technology advances, energy efficiency becomes a key factor in both product design and operational cost. Devices that overheat tend to require more energy to function properly, which can lead to higher operating costs. Custom heat sinks, by efficiently dissipating heat, help reduce the overall power consumption of a device.

By keeping temperatures within optimal ranges, custom heat sinks ensure that the internal components don’t have to work harder than necessary to maintain performance. This not only conserves energy but also reduces the strain on the power supply and other critical components, further enhancing the device’s energy efficiency. For industries looking to reduce their environmental footprint or for consumers looking to save on energy bills, custom heat sinks offer a simple yet highly effective solution.

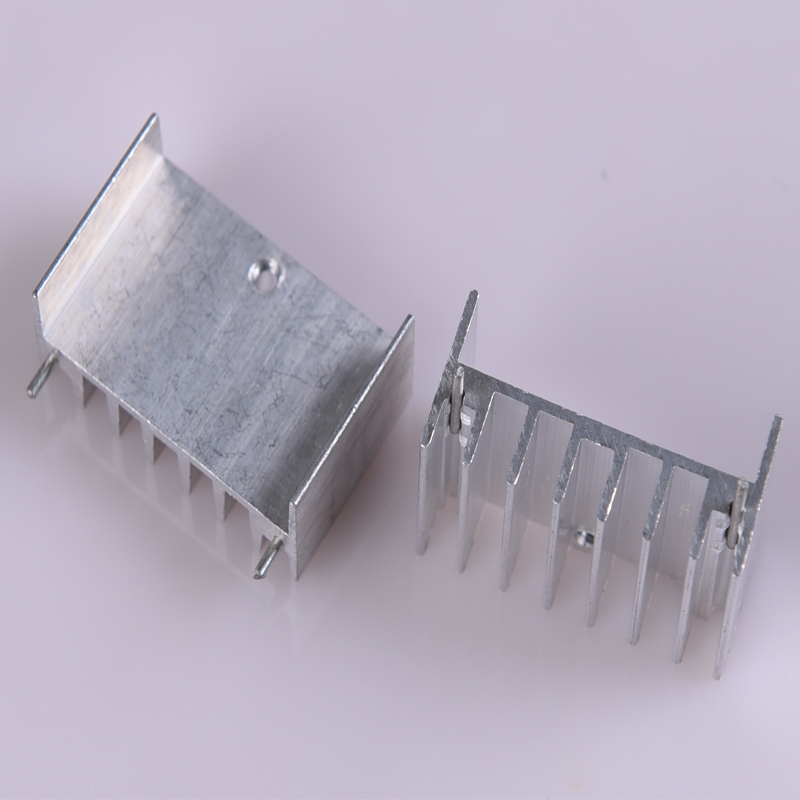

Compact, Versatile Designs for Tight Spaces

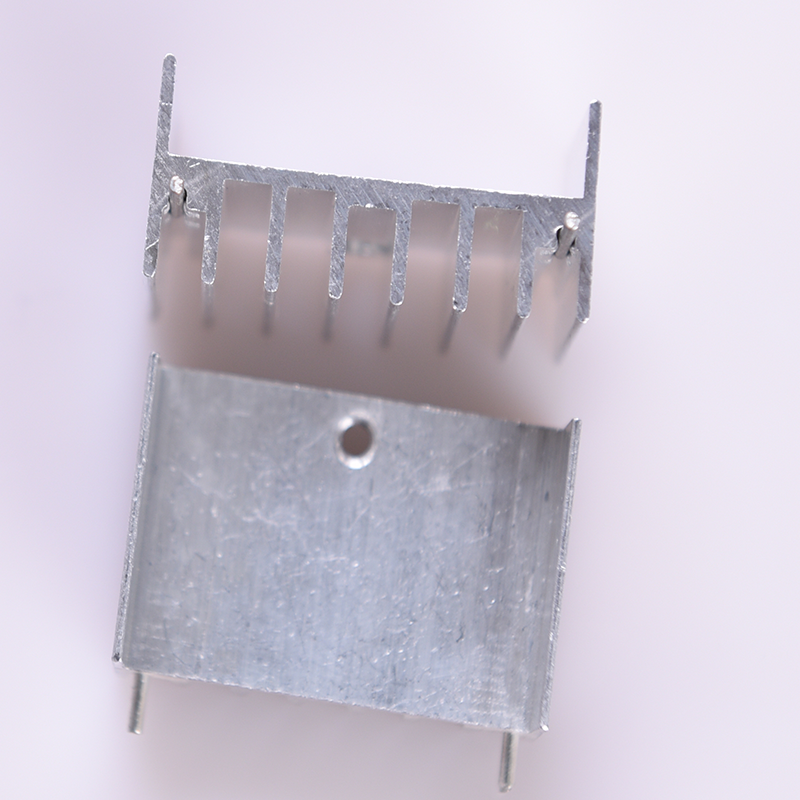

Another distinct advantage of custom heat sinks is their ability to fit into uniquely shaped and tight spaces. In many modern electronics, there is a push toward miniaturization, which means that components are packed more closely together, and available space for heat dissipation is limited. Custom heat sinks can be designed to fit precisely within the available space while still providing effective thermal management.

At Topmetalstamping, we have the expertise and technology to create intricate and compact heat sink designs that are ideal for devices with limited space. Whether you’re working with a slim smartphone, a small medical device, or an ultra-compact computer, our custom heat sinks can be crafted to meet the most demanding size and shape requirements.

Why Choose Topmetalstamping for Your Custom Heat Sink Needs?

At Topmetalstamping, we pride ourselves on our commitment to quality, innovation, and precision. Our team of engineers works closely with you to develop custom heat sinks that meet the specific thermal management requirements of your electronic devices. With years of experience and a customer-focused approach, we ensure that each heat sink we produce delivers optimal performance, energy efficiency, and reliability.

We understand that each device is unique, and we offer a range of materials, shapes, and sizes to meet your exact specifications. Our advanced manufacturing processes and stringent quality control measures ensure that every heat sink we produce is built to last. With Topmetalstamping as your partner, you can be confident that your electronic devices will operate at peak efficiency, regardless of their size, complexity, or power requirements.

Conclusion

In conclusion, custom heat sinks are indispensable components in the design and manufacturing of modern electronic devices. Their ability to provide efficient heat dissipation, extend device lifespans, enhance reliability, and improve energy efficiency makes them essential for any high-performance electronic application. As technology continues to evolve and devices become more compact and powerful, the importance of custom heat sinks will only grow.

At Topmetalstamping, we’re here to provide you with the expert solutions and custom designs necessary for effective thermal management. Whether you’re designing consumer electronics, medical devices, or industrial equipment, our custom heat sinks will ensure your devices perform optimally and reliably for years to come. Contact us today to discuss your needs, and let us help you optimize your devices with the best heat sink solutions available in the industry.