In the world of electronics, it’s easy to feel overwhelmed by the sheer variety of components, each serving a unique function. One such component that often gets overlooked is the humble electrical terminal. These small, seemingly simple devices play a vital role in ensuring smooth electrical connections, providing secure and reliable paths for current to flow through circuits. Whether you’re working on an automotive repair, assembling a computer, or designing a complex industrial system, selecting the right terminal is essential. This guide will explore the top 10 types of electrical terminals and their applications, helping you make the best choices for your projects.

What is an Electrical Terminal?

An electrical terminal is a device that connects electrical wires together, ensuring the uninterrupted flow of current between components. Think of it as a bridge that links different parts of a circuit, allowing electricity to move from one point to another. Terminals come in a wide range of designs and materials, each tailored to specific tasks and environments. They are critical in industries ranging from automotive to industrial machinery, home appliances, and consumer electronics.

Choosing the right electrical terminal can save time, improve reliability, and prevent costly mistakes. In this article, we’ll break down the top 10 types of terminals, helping you select the best one for your next project.

1. Ring Terminals

Features and Applications

Ring terminals are one of the most common and reliable types of electrical terminals. Their design consists of a metal ring with a hole in the center, which can be fastened onto a stud or screw. This ring design ensures a stable connection, making it ideal for environments with vibrations or movement, where other types of terminals might fail.

Applications: Ring terminals are widely used in automotive wiring, industrial machinery, and home appliances. They are especially useful for battery connections, alternators, and grounding points, where a secure, long-lasting connection is critical.

Advantages: Once bolted, ring terminals provide a solid, permanent connection, which resists loosening over time. They’re also easy to install.

Limitations: Ring terminals require a stud or screw for installation, making them unsuitable for applications where these are not available. Additionally, they aren’t ideal for applications requiring frequent disconnections.

2. Spade Terminals

Features and Applications

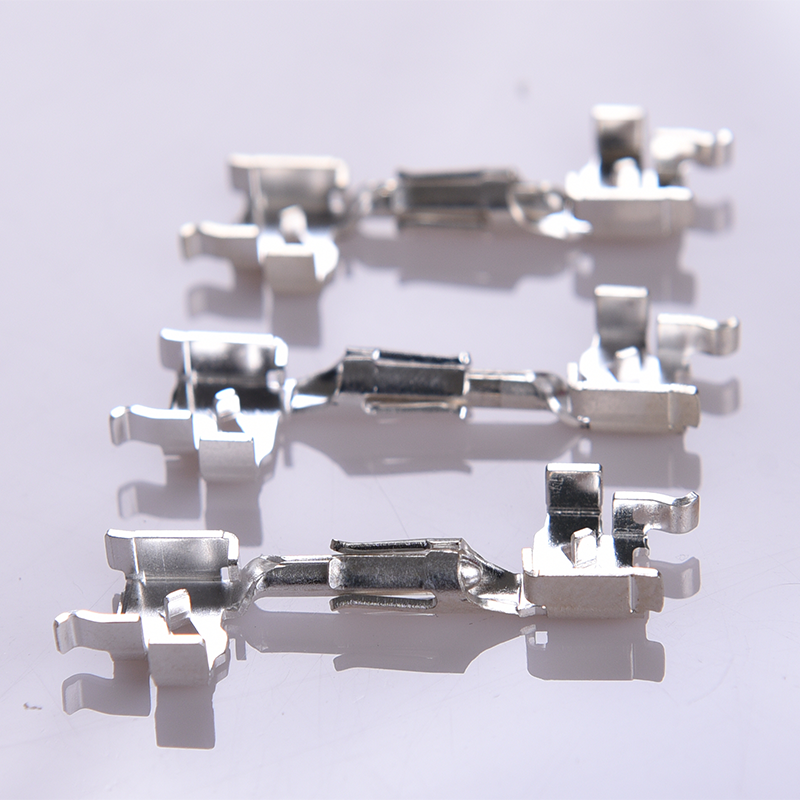

Spade terminals, also known as fork terminals, are characterized by their forked design, which makes them easy to connect and disconnect from screws or studs without removing the fastening hardware.

Applications: Spade terminals are ideal for automotive and home appliance wiring where components may need to be connected or disconnected regularly. They’re commonly used in control panels and other systems requiring ease of installation and maintenance.

Advantages: Their U-shape allows for easy and quick connections. They are also available in both insulated and non-insulated versions, offering flexibility for various environments.

Limitations: While they are easy to use, spade terminals are less secure than ring terminals and may slip off if the connection is subjected to excessive vibration or movement.

3. Butt Connectors

Features and Applications

Butt connectors are cylindrical terminals used to join two wires end-to-end, creating a secure, inline connection. They come in both insulated and non-insulated versions, with some featuring heat-shrink tubing for added protection.

Applications: Butt connectors are commonly used in automotive and marine applications, as well as in household wiring projects. They’re perfect for splicing wires or extending wire lengths in tight spaces.

Advantages: Butt connectors provide a neat, compact connection, and the crimping process ensures that the wires are firmly attached, preventing loose connections that could lead to failures.

Limitations: Butt connectors may not be suitable for applications involving high current, as the connection could weaken over time.

4. Bullet Connectors

Features and Applications

Bullet connectors consist of a cylindrical metal component that fits into a matching socket, creating a quick and secure connection. These connectors are often used where fast disconnection is needed.

Applications: Bullet connectors are common in automotive, industrial, and marine applications, where components may need to be connected or disconnected frequently.

Advantages: They provide a reliable, quick-disconnect connection that’s easy to install and remove.

Limitations: Bullet connectors are generally better suited for low to medium current applications and may not be suitable for high-current systems.

5. Flag Terminals

Features and Applications

Flag terminals have a unique design that allows for a right-angle connection between the wire and the terminal. Their compact, perpendicular structure is perfect for tight spaces where the terminal needs to fit into a specific direction.

Applications: Flag terminals are used in consumer electronics like televisions and computers, where space-saving and efficient wiring are essential.

Advantages: The right-angle design helps save space and maintain a neat, organized wiring layout. They’re particularly useful in applications where wires need to be routed in a particular direction.

Limitations: Their specialized design may limit their use in certain applications, and they may not provide as secure a connection as other terminal types.

6. Pin Terminals

Features and Applications

Pin terminals are slender, cylindrical connectors that are inserted into terminal blocks or connectors. Their pin-like design ensures a secure, reliable contact, making them ideal for complex systems requiring multiple wire connections.

Applications: Pin terminals are used in a variety of applications, including circuit boards and control systems, where neatness and organization are important.

Advantages: Pin terminals simplify circuit design and reduce the risk of shorts, especially in environments prone to vibration.

Limitations: They may not be suitable for high-current applications and require careful installation to ensure a secure connection.

7. Fork Terminals

Features and Applications

Fork terminals have an open-ended, fork-like design, which makes them easy to attach or detach from screws or studs without removing the fastening hardware.

Applications: Fork terminals are often used in automotive wiring, where components need to be frequently connected or disconnected. They are also useful in industrial machinery and household appliances.

Advantages: Easy to connect and disconnect, and they provide a secure, reliable connection that resists loosening.

Limitations: Fork terminals are not as secure as ring terminals and may be unsuitable for high-vibration environments.

8. Quick-Disconnect Terminals

Features and Applications

Quick-disconnect terminals are designed for fast, tool-free connections. They consist of a male and female component, where the male end slides into the female end to create a secure, detachable connection.

Applications: These terminals are commonly found in automotive, marine, and industrial applications, where components may need to be quickly replaced or serviced.

Advantages: Quick-disconnect terminals are perfect for applications requiring frequent connection and disconnection. They provide a reliable connection that can be made or broken quickly.

Limitations: They are typically used for low to medium current applications and may not be suitable for high-power systems.

9. Wire Nuts

Features and Applications

Wire nuts are twist-on connectors that are used to join multiple wires securely. Made of plastic or polymer, they feature an internal metal coil that grips the wires when twisted together.

Applications: Wire nuts are common in household electrical systems, especially in junction boxes where multiple wires need to be connected securely.

Advantages: They’re easy to use and provide a secure, insulated connection. Their ability to connect multiple wires at once makes them useful for various electrical projects.

Limitations: Wire nuts are not suitable for applications involving moisture or extreme temperatures, as their plastic casing can degrade over time.

10. Insulated vs. Non-Insulated Terminals

Features and Applications

Insulated terminals feature an extra layer of protection around the metal part of the connector. This insulation prevents accidental contact and reduces the risk of electrical shorts. Non-insulated terminals, on the other hand, do not have this layer of insulation, making them more compact but also less safe in certain environments.

Applications: Insulated terminals are ideal for applications where electrical safety is a concern, such as automotive and marine wiring. Non-insulated terminals are often used in industrial settings where the wiring is contained in panels or enclosures.

Advantages: Insulated terminals provide extra safety and protection against accidental contact, while non-insulated terminals are more compact and often used in controlled environments.

Limitations: Insulated terminals can be bulkier, while non-insulated terminals may expose wiring to potential safety hazards.

How to Choose the Right Terminal for Your Application

When selecting the right terminal, consider factors such as material (copper, brass, or aluminum), size (matching wire gauge), and environmental conditions. Whether you need a terminal for automotive, industrial, or consumer electronics, the right choice will depend on your specific application.

Conclusion

Selecting the right electrical terminal is a key decision that can affect the reliability and performance of your electrical systems. If you need expert advice or high-quality terminals for your projects, Topmetalstamping is here to help. Our range of electrical terminals, manufactured to the highest standards, ensures secure connections for a variety of applications. Whether you’re designing a complex circuit or working on a DIY project, we’ve got the right solution for you.Contact us today for professional assistance in selecting the best terminals for your needs.