Hello,guys,this is Topmetalstamping,welcome to the world of progressive die stamping—a manufacturing technique that’s revolutionizing how we create metal parts. Whether you’re looking to produce a batch of components quickly or seeking a cost-effective solution for high-volume production, progressive die stamping has got you covered. Let’s dive into what makes this method so effective and why it might just be the perfect fit for your next project.

What is Progressive Die Stamping?

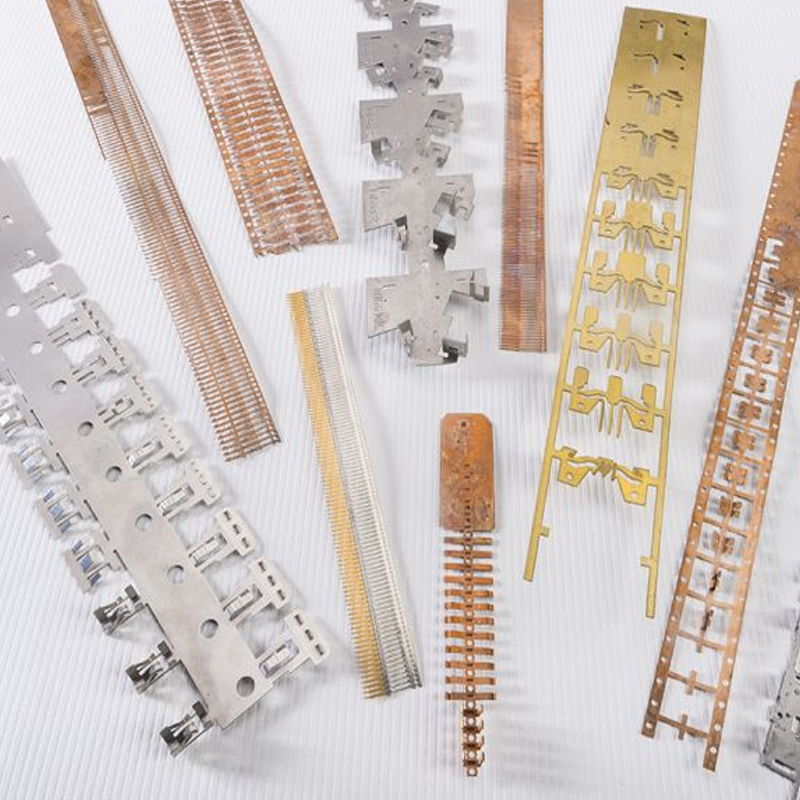

Imagine a well-oiled assembly line where each station has a specific job, and the workpiece moves through each station like a well-choreographed dance. That’s progressive die stamping in action. This process involves feeding a metal strip through a series of stamping stations within a die, each performing a different task—like bending, punching, or cutting—until the part reaches its final form. Once it’s done, the part is separated from the strip and ready for use.

Why Choose Progressive Die Stamping?

You might be wondering, “What’s so great about progressive die stamping?” Here’s why it’s becoming the go-to method for many manufacturers:

- Speedy Production: If you need parts fast, progressive die stamping is your best friend. The continuous feeding of parts through the die means you can churn out high volumes in no time. Perfect for those big orders!

- Less Waste: Unlike other methods that can leave you with a lot of scrap metal, progressive die stamping is all about efficiency. It minimizes waste, making it not only cost-effective but also environmentally friendly.

- Design Flexibility: Whether you need simple shapes or intricate designs, progressive die stamping can handle it. It gives you the freedom to get creative with your part designs.

- High Production Capacity: Got a big order? No problem. Progressive die stamping can handle long production runs, getting your parts out quickly and efficiently.

- Consistency and Quality: The use of high-quality tooling ensures that each part is made to the same high standard. You’ll get consistent quality every time.

- Cost Savings: With lower waste, faster setup, and high production speeds, you’ll see a reduction in the cost per part. Plus, the automated process means fewer labor costs and reduced risk of workplace injuries.

- Precision: The process is designed to produce parts with tight tolerances, ensuring your components are accurate and reliable.

How Does the Progressive Die Stamping Process Work?

Here’s a simple breakdown of the process:

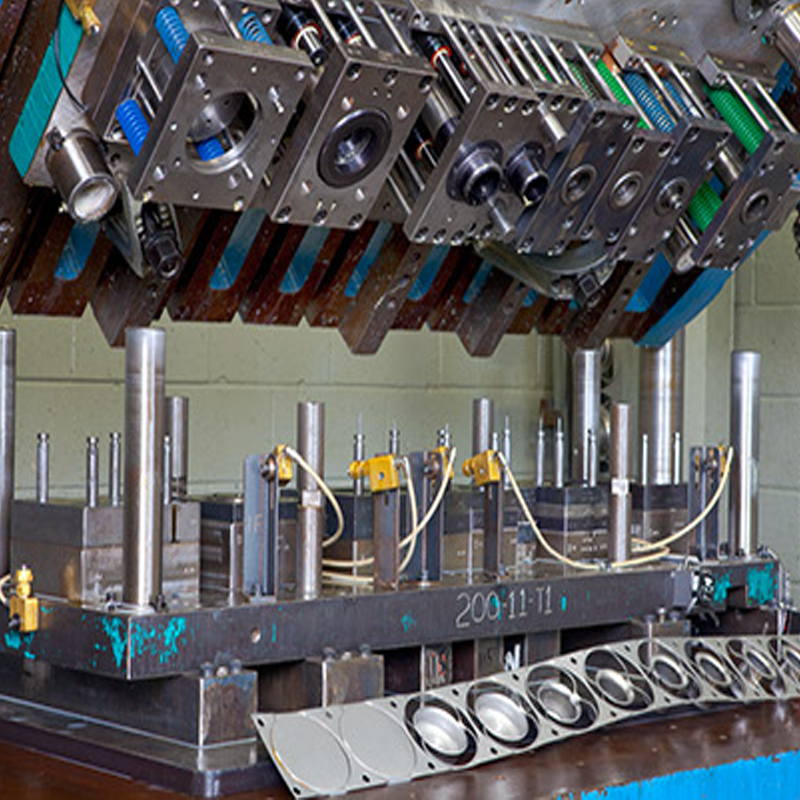

- Tooling Creation: Skilled toolmakers craft a die set with all the tools needed for production. This die doesn’t change throughout the process, so the workpiece moves through seamlessly.

- Setting Up the Die: The die is installed in a stamping press. The press moves up and down, opening and closing the die to perform the various stamping operations.

- Feeding the Metal Strip: A metal strip is fed into the die. As the strip moves through, each station in the die performs its task.

- Stamping Operations: The die shapes the workpiece through various operations—like bending, cutting, or embossing—until the part reaches its final shape.

- Ejecting the Finished Part: Once the part is fully formed, it’s ejected from the die and separated from the strip.

What Equipment Do You Need?

To get the most out of progressive die stamping, you’ll need some essential equipment:

– Stamping Presses: These provide the force needed to stamp the metal.

– Progressive Tooling: The die set with all the necessary tools.

– Coil Feed Line: Feeds the metal strip into the die.

Where is Progressive Die Stamping Used?

This technique is versatile and widely used in various industries, including:

– Electronics: For connectors and housings.

– Food and Beverage: For packaging and machinery parts.

– Medical: For components used in medical devices.

– Appliances: For household and industrial appliance parts.

– Automotive: For vehicle components like brackets and panels.

Progressive Die Stamping vs. Other Methods

You might be weighing your options, so here’s a quick comparison:

– Compound Metal Stamping: Good for flat parts but can be slower for complex designs.

– Transfer Die Stamping: Ideal for complex or large parts but involves moving the workpiece between stations.

– Traditional Metal Stamping: Best for small runs but slower and more costly for large volumes.

At Topmetalstamping, we’re experts in progressive die stamping and can tailor our services to meet your specific needs. Whether you need custom designs, complex geometries, or high-volume production, we’ve got the tools and expertise to deliver. Our commitment to quality and efficiency ensures that your parts are made to your exact specifications.

Ready to explore the benefits of progressive die stamping for your project? Contact us today to discuss your needs and see how we can help bring your ideas to life. Let’s make your manufacturing process smoother and more cost-effective—together!

For all your stamping needs, Topmetalstamping is here to provide top-notch solutions that meet your unique requirements. Get in touch to learn more about our progressive die stamping capabilities and how we can assist you with your next project.